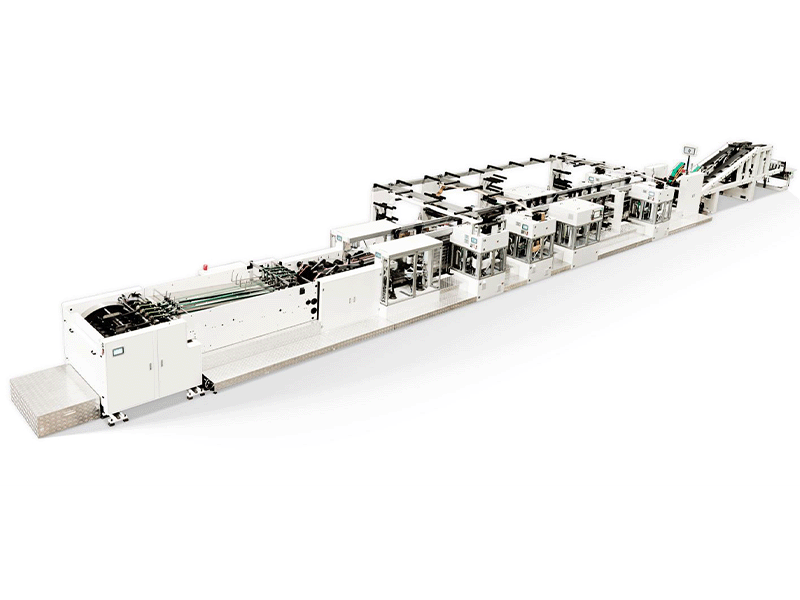

In the modern packaging industry, bottom gluing machines have become indispensable for manufacturers aiming to optimize efficiency, reduce labor costs, and deliver high-quality packaging solutions. These machines automate the crucial process of folding and gluing the bottom flaps of cartons and paper bags, transforming flat blanks into sturdy, ready-to-use packaging suitable for a wide range of industries, such as food, pharmaceuticals, cosmetics, electronics, and e-commerce. This guide will help you gain a deep understanding of bottom gluing machines, their working principles, benefits, and the most important factors to consider when making a purchase, while also introducing the strengths of DESHENG as a leading manufacturer.

What Are Bottom Gluing Machines?

Bottom gluing machines are specialized equipment designed to fold and glue the bottom flaps of cartons or paper bags, creating a secure base that supports the contents during handling and transport. They play a vital role in ensuring packaging integrity, speed, and consistency, which are crucial for businesses that require reliable and efficient packaging operations.

Types of Bottom Gluing Machines

There are several types of bottom gluing machines, each tailored for specific packaging needs and production environments:

Crash-Lock Bottom Folder Gluers: These machines automatically fold and glue the bottom flaps so that boxes lock into place when opened, providing a sturdy base without manual assembly. This is ideal for heavier products or applications where easy assembly is important.

Straight-Line Folder Gluers: These machines fold and glue flaps in a linear fashion, making them suitable for standard carton boxes and high-speed production lines.

Paper Bag Bottom Gluing Machines: Designed specifically for paper bags, these machines insert bottom cardboard, apply glue, and close the bottom automatically, ensuring precision and speed in paper bag manufacturing.

How Do Bottom Gluing Machines Work?

The operation of bottom gluing machines typically involves several automated stages:

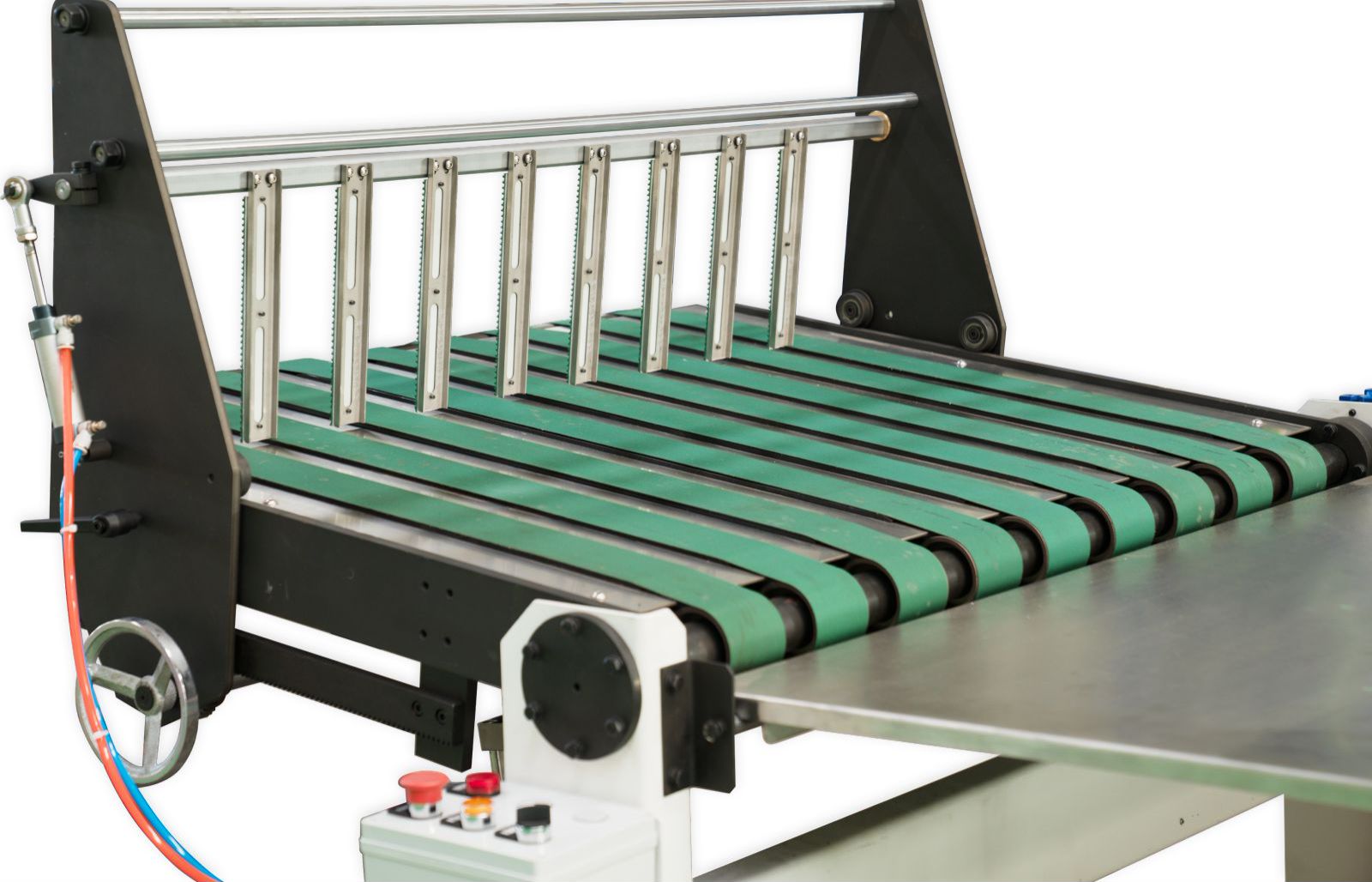

Feeding: Flat die-cut blanks or paper bags are automatically fed into the machine, ensuring a continuous and efficient workflow.

Folding: The machine folds the minor and major flaps in a precise sequence, preparing the packaging for gluing.

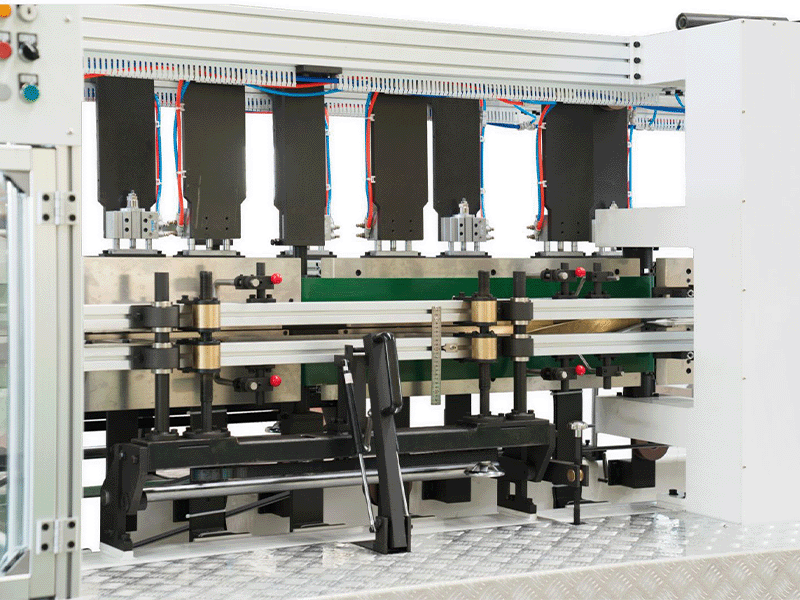

Gluing: Adhesive, usually hot melt or water-based, is applied accurately to designated areas using nozzles or rollers. Advanced machines allow for independent control of glue length and quantity for optimal bonding.

Compression: The folded and glued bottoms are compressed to ensure a strong, durable bond, with compression rollers or plates holding the flaps together until the adhesive cures.

Inspection and Ejection: Automated sensors and cameras inspect the glued boxes or bags for defects, such as misfolds or insufficient glue. Defective products are ejected to maintain high quality standards.

Stacking: Finished boxes or bags are stacked and prepared for shipment, often with integrated automated stacking systems.

Key Benefits of Bottom Gluing Machines

The adoption of bottom gluing machines brings significant advantages to packaging operations:

Increased Efficiency: Automated folding and gluing significantly speed up production compared to manual assembly, enabling high throughput suitable for large-scale packaging operations.

Consistent Quality: Precision glue application and folding mechanisms reduce errors and ensure uniform, strong seals, enhancing product protection and presentation.

Labor Savings: Automation reduces the need for manual labor, lowering operational costs and minimizing human error.

Versatility: Modern machines can handle a wide range of materials (cardboard, corrugated board, paperboard) and box styles (straight-line, crash-lock, multi-corner), adapting to diverse packaging needs.

Improved Safety: Automated inspection and ejection systems help maintain zero-defect production, reducing waste and rework.

Sustainability: Many bottom gluing machines support eco-friendly materials such as recycled paperboard and biodegradable adhesives, aligning with growing environmental regulations and consumer demand.

Essential Factors to Consider When Buying a Bottom Gluing Machine

When choosing a bottom gluing machine, it's crucial to approach the decision holistically, considering how each aspect impacts your production goals, operational efficiency, and long-term business success. Instead of viewing each factor in isolation, think about how they interconnect and support your overall packaging strategy.

1. Production Volume and Speed

Begin by evaluating your current and projected packaging output. If your business handles high-volume orders or expects rapid growth, prioritize machines with faster setup times, higher speeds, and robust throughput capabilities. For smaller-scale operations, a simpler machine may offer the flexibility and efficiency needed without unnecessary costs or complexity.

2. Material Compatibility and Box Design Complexity

Your choice of machine must align with the types of materials and packaging designs you use or plan to introduce. Some machines are optimized for lightweight paperboard, while others can handle heavier corrugated materials or laminated substrates. Similarly, if your packaging involves intricate designs—such as crash-lock bottoms or multipoint gluing—invest in a machine with advanced features and flexibility to future-proof your production process.

3. Automation and Ease of Use

Modern bottom gluing machines range from semi-automatic to fully automated systems. Higher automation levels reduce manual intervention, speed up changeovers, and minimize setup times, which is particularly valuable for businesses with frequent product changes or high labor costs. User-friendly interfaces, such as touchscreen controls and programmable settings, also enhance operator efficiency and reduce the risk of errors.

4. Glue Type and Application Precision

Consider the types of adhesives (hot melt, water-based, or specialty glues) compatible with your products and environmental requirements. Machines that offer precise glue application, independent control of glue length and quantity, and minimal waste will help you achieve both quality and sustainability targets.

5. Maintenance, After-Sales Support, and Upgradability

Reliable after-sales support, including warranties, spare parts availability, and responsive technical assistance, is essential for minimizing downtime and extending the lifespan of your investment. Choose a supplier that offers comprehensive maintenance plans and options for future upgrades or retrofits, ensuring your machine remains efficient and competitive as your business evolves.

6. Flexibility and Changeover Efficiency

If your production line handles multiple box sizes or styles, look for machines with quick changeover features and modular designs. This flexibility allows you to adapt to changing market demands and customer requirements without significant delays or additional costs.

7. Budget and Total Cost of Ownership

While initial investment is a key consideration, weigh it against long-term operational savings, efficiency gains, and potential for business growth. Sometimes, a higher upfront cost is justified by reduced labor expenses, lower defect rates, and increased production capacity over time.

Why Choose DESHENG?

When it comes to selecting a bottom gluing machine, DESHENG stands out as a trusted bottom gluing machine partner and industry leader. DESHENG's machines are renowned for their intelligent automation, modular design, and eco-friendly features, making them ideal for businesses seeking to enhance efficiency and sustainability in packaging production.

Cutting-Edge Technology: DESHENG machines feature servo intelligent systems, modular designs, and automatic adjustment capabilities, ensuring precise, high-speed production for a wide range of bag and box types and sizes.

Unmatched Efficiency: Fully automated processes minimize manual intervention, reduce downtime, and maximize output, helping you meet even the most demanding production schedules.

Superior Quality Control: Integrated inspection systems guarantee consistent, defect-free packaging, enhancing your brand's reputation and customer satisfaction.

Comprehensive Support: From initial consultation to after-sales service, DESHENG provides expert guidance and technical support, ensuring your production line runs smoothly at all times.

Sustainability Focus: DESHENG's machines are designed for eco-friendly materials and processes, helping your business align with global environmental standards and consumer expectations.

Whether you are upgrading outdated equipment or launching a new packaging line, DESHENG's advanced solutions will empower you to stay ahead in a competitive market. Investing in a DESHENG bottom gluing machine is not just a smart business decision—it's a strategic move that positions your operation for long-term success.

Conclusion

Bottom gluing machines are a cornerstone of modern packaging operations, delivering efficiency, precision, and reliability in producing secure carton and paper bag bottoms.

If you're looking for a trusted partner in packaging machinery, DESHENG offers state-of-the-art bottom gluing machines that can transform your production line, enhance your product's market appeal, and provide a lasting competitive edge. Reach out to DESHENG today to discover how our advanced solutions can help your business achieve new heights of productivity and quality.