The packaging industry is rapidly evolving, driven by demands for efficiency, consistency, and cost-effective production. For manufacturers of cement, agricultural products, or granular materials, the choice of a tube forming machine is critical. While traditional systems have served factories for years, high-speed intelligent tube forming machines offer modern solutions that maximize productivity and quality.

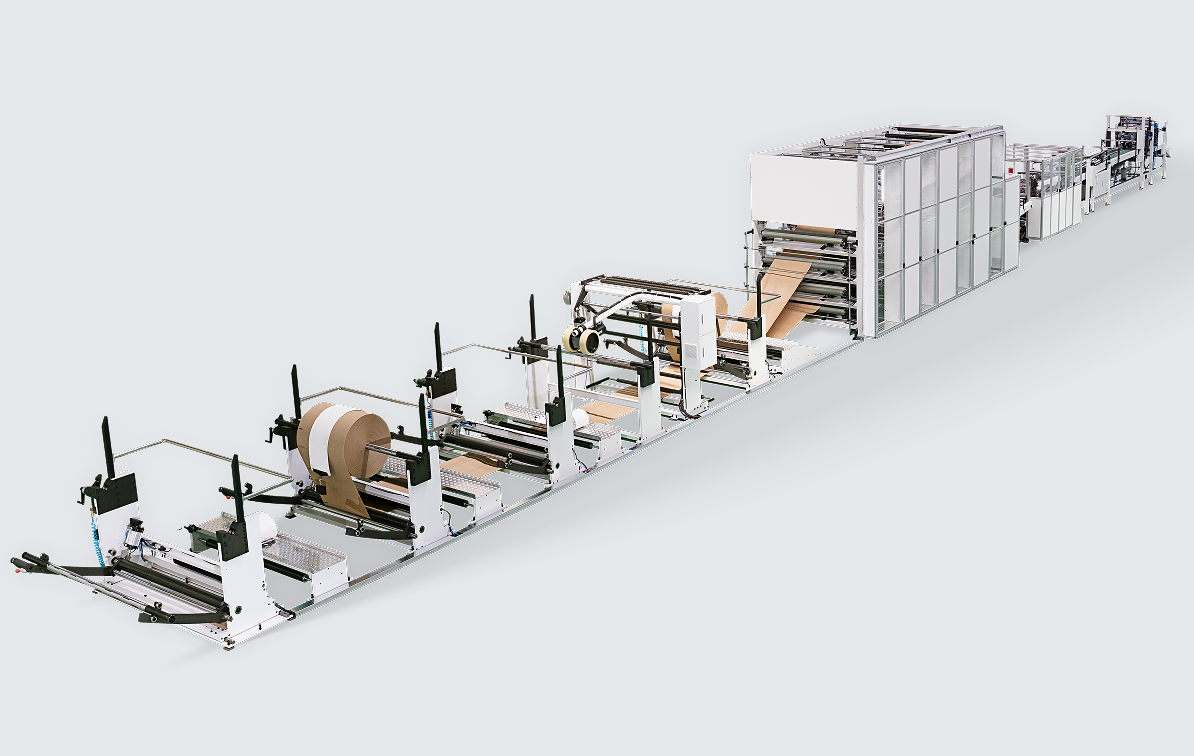

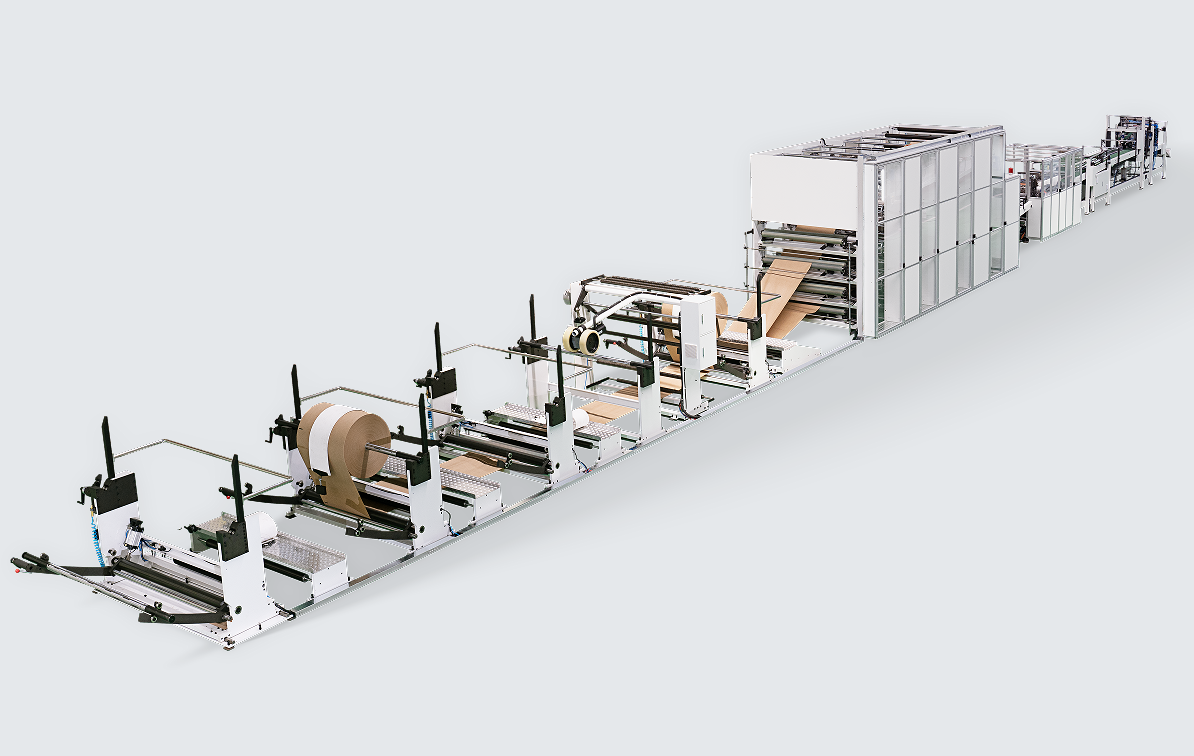

At DESHENG, our high-speed tube forming machines are designed to integrate seamlessly into paper valve bag production lines, providing precision, reliability, and automation that help factories meet growing production demands. In this article, we compare high-speed intelligent machines with traditional systems to help you decide which solution fits your plant.

1. Production Efficiency and Throughput

Traditional Systems

Traditional tube forming machines often rely on manual feeding and adjustment. Operators are needed at almost every step, including aligning the paper, cutting tubes, and handling glued sections. This manual involvement slows down production, increases downtime, and limits the number of bags produced per hour.

High-Speed Intelligent Tube Forming Machines

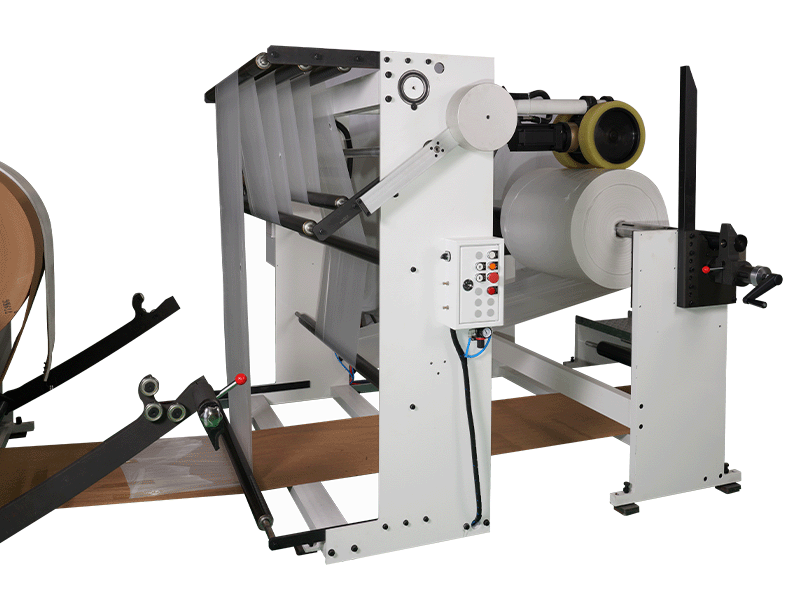

Our DESHENG high-speed tube forming machines automate feeding, cutting, gluing, and tube formation. Automation enables continuous production with minimal pauses, allowing your plant to achieve higher throughput consistently.

- Continuous Operation: Automated paper feeding reduces stops and ensures stable output.

- Integrated Workflow: The machine works in tandem with valve bag base machines for a smooth production line.

- Operator-Friendly Interface: Operators can monitor production easily and make adjustments without halting the line.

In short, upgrading to an intelligent machine significantly enhances production speed and efficiency, making it ideal for medium to large-scale plants.

2. Product Quality and Consistency

Challenges of Traditional Systems

Manual systems often produce inconsistent results. Variations in tube dimensions, glue application, or alignment can lead to weak seals, uneven bag structures, and higher rejection rates.

Advantages of High-Speed Intelligent Machines

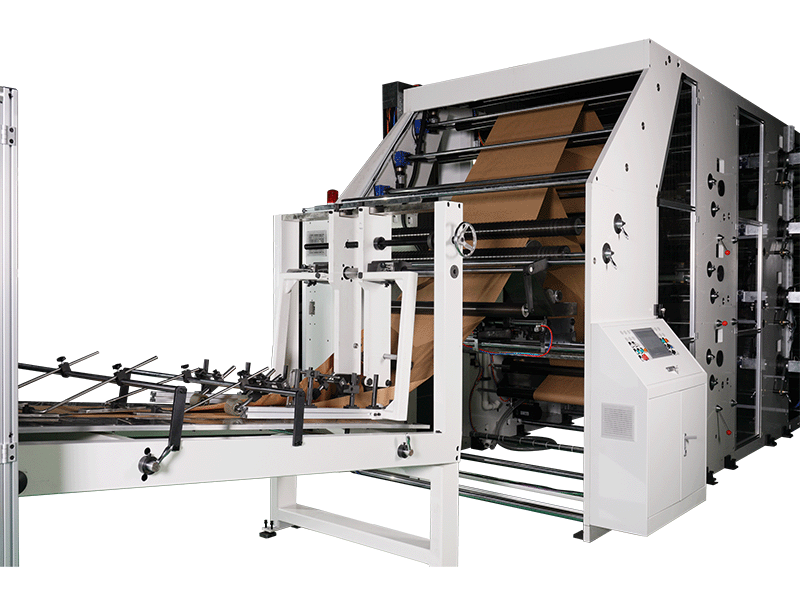

Our intelligent tube forming machines are engineered for precision and consistency:

- Servo-Controlled Alignment: Ensures uniform tube size and shape.

- Precise Glue Application: Provides strong and reliable sealing for each bag.

- Automated Quality Monitoring: Reduces errors caused by manual handling.

By producing consistent, high-quality bags, manufacturers minimize waste and maintain customer satisfaction. DESHENG machines deliver uniformity across every production cycle, which is crucial for cement and other granular product packaging.

3. Labor Requirements and Safety

Traditional Systems

Manual systems require a larger workforce to maintain output. Workers must constantly adjust settings, handle paper rolls, and manage glued sections. This dependence on human labor can increase operating costs and the risk of human error.

High-Speed Intelligent Machines

By automating key steps, DESHENG high-speed machines reduce labor needs and simplify operations:

- Lower Workforce Dependency: Fewer operators are needed to manage the line.

- Reduced Human Error: Automation ensures consistent tube forming and gluing.

- Safer Workplace: Operators spend less time near moving or heated components, reducing risk of accidents.

Automation also allows operators to focus on supervision and quality control rather than repetitive manual tasks.

4. Integration and Flexibility

Traditional Systems

Integrating traditional machines with other parts of the production line can be complicated due to different speeds and mechanical controls. Adjustments are often manual, leading to downtime when switching bag types or materials.

High-Speed Intelligent Machines

Our DESHENG machines are designed for seamless integration with other production line equipment:

- Smart Connectivity: Interfaces easily with valve bag base machines and packaging lines.

- Real-Time Adjustments: Built-in sensors adjust paper feed and cutting to maintain consistency.

- End-to-End Automation: Tube forming, gluing, and bag base assembly are synchronized for smooth workflow.

Flexible automation ensures that manufacturers can handle different bag sizes and materials without extensive downtime or manual adjustments.

5. Cost Efficiency and Sustainability

Traditional Systems

While the initial investment for manual or semi-automatic systems is lower, long-term costs can be higher due to labor, waste, and inefficiencies. Inconsistent glue application or misaligned tubes can increase material wastage, and frequent human intervention adds operational expenses.

High-Speed Intelligent Machines

DESHENG high-speed tube forming machines optimize costs in several ways:

- Material Savings: Precise cutting and glue application reduce paper and adhesive waste.

- Energy Efficiency: Optimized design ensures minimal energy consumption.

- Durable Design: Machines are built for long-term operation with minimal maintenance.

By combining efficiency with sustainable practices, intelligent machines provide significant long-term savings and environmental benefits.

6. When to Choose Each System

Traditional Systems

- Suitable for small-scale production or plants with limited budgets.

- Ideal for plants producing multiple small batches or experimental runs.

High-Speed Intelligent Machines

- Best for medium to large-scale production with high demand.

- Recommended for manufacturers seeking long-term efficiency, consistent quality, and automation.

At DESHENG, we provide solutions that fit a wide range of production scales. Our high-speed tube forming machines help plants modernize their operations, reduce costs, and achieve higher productivity with minimal workforce dependency.

Conclusion

Choosing the right tube forming machine depends on your production needs, budget, and growth strategy. Traditional systems are simple and flexible, but they often limit throughput and consistency. High-speed intelligent tube forming machines, such as those from DESHENG, offer automation, precision, and integration that maximize production efficiency, reduce labor, and support sustainable practices.

Upgrading to a DESHENG high-speed intelligent tube forming machine is a strategic investment for any manufacturer looking to enhance performance, ensure consistent quality, and remain competitive in the modern industrial packaging market.