In today’s eco-conscious and efficiency-driven marketplace, the demand for high-quality paper bags is skyrocketing. As businesses and consumers increasingly shift away from plastics, the need for reliable, scalable, and sustainable packaging solutions has never been greater. At the heart of this transformation is the automatic bottom gluing machine-a technological breakthrough that is fundamentally changing how paper bags are produced, ensuring speed, consistency, and cost-effectiveness at every stage.

The Critical Role of Bottom Gluing in Paper Bag Manufacturing

The bottom of a paper bag is its foundation-responsible for carrying weight, maintaining shape, and protecting contents. Traditionally, gluing the bottom was a manual, time-consuming process prone to inconsistencies and inefficiencies. With the advent of automatic bottom gluing machines, this crucial step is now performed with unmatched precision and reliability, setting a new standard for the industry.

How Automatic Bottom Gluing Machines Work

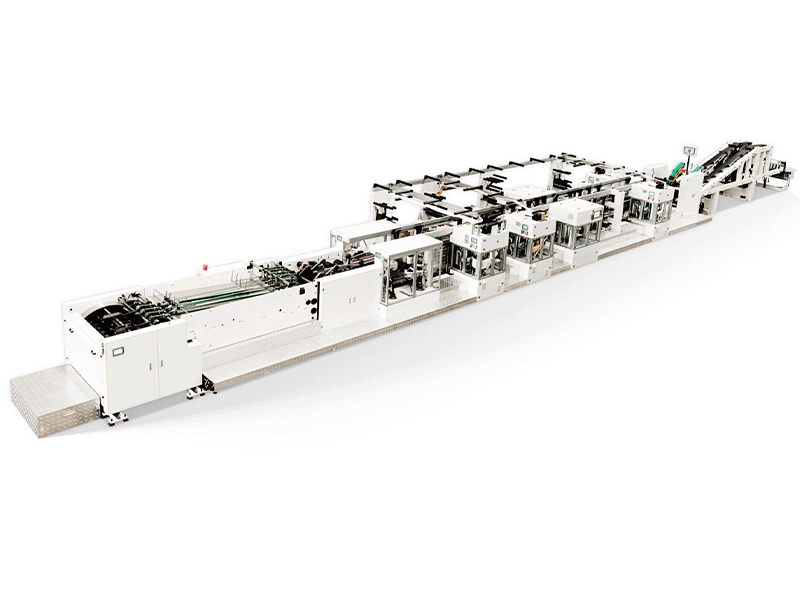

Automatic bottom gluing machines are sophisticated systems that integrate several essential processes into a seamless, automated workflow:

Feeding: Pre-cut paper blanks or rolls are automatically fed into the machine, ensuring a continuous supply and minimizing manual intervention.

Folding: The machine folds both minor and major flaps of the bag's bottom in a precise sequence, preparing them for gluing.

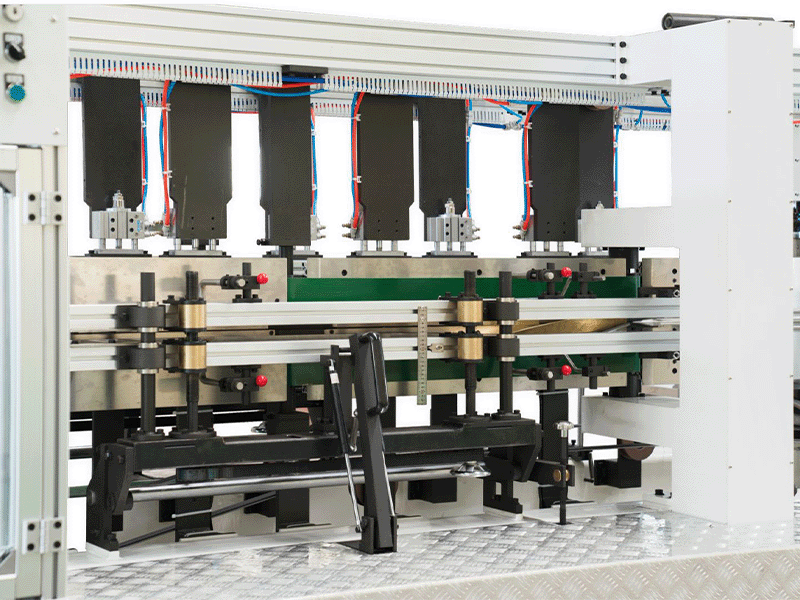

Gluing: Using hot melt or water-based adhesives, glue is applied with pinpoint accuracy, ensuring a strong, uniform seal.

Compression: The glued flaps are compressed under controlled pressure, guaranteeing a durable bond that withstands handling and transport.

Inspection & Ejection: Advanced sensors and cameras inspect each bag for defects, automatically rejecting those that don't meet quality standards.

Stacking: Finished bags are counted and stacked, streamlining downstream packaging and logistics.

By automating these steps, manufacturers can achieve high-speed, high-volume production with minimal labor and maximum consistency.

Key Advantages of Automatic Bottom Gluing Machines

1. Dramatic Efficiency Gains

Automatic bottom gluing machines can produce thousands of paper bags per hour, far surpassing manual or semi-automatic methods. This high throughput is critical for meeting the demands of large retailers, food service providers, and e-commerce platforms.

2. Consistent, High-Quality Output

Precision engineering and automated glue application ensure every bag meets stringent quality standards. Uniform folding and sealing eliminate the risk of weak spots, leaks, or structural failures.

3. Reduced Labor and Operational Costs

By automating labor-intensive tasks, these machines reduce reliance on manual labor, lower operational expenses, and minimize human error. Staff can be reallocated to higher-value activities, such as quality assurance and process optimization.

4. Versatility and Adaptability

Modern machines can handle a wide range of bag sizes, shapes, and materials, including multi-layer kraft paper and specialty coatings. Quick-change mechanisms and programmable settings allow for rapid transitions between product types.

5. Enhanced Safety and Ergonomics

Automation reduces repetitive strain and exposure to adhesives, while built-in safety features (like emergency stops and protective covers) protect operators from accidents.

6. Sustainability and Waste Reduction

Automatic bottom gluing machines are designed to work with recycled and biodegradable materials, supporting environmental goals. Precise glue application minimizes waste, and advanced inspection systems reduce the number of defective products.

Technological Innovations Driving the Industry Forward

The latest automatic bottom gluing machines incorporate several advanced technologies:

Servo Motor Control: Ensures precise, synchronized movement of folding and gluing components for consistent results.

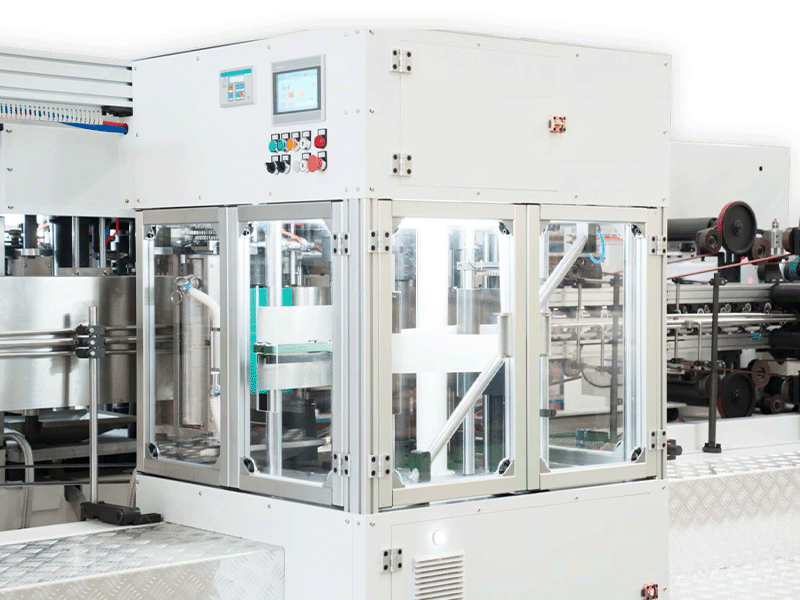

Touchscreen Interfaces: Allow operators to easily set parameters, monitor production, and troubleshoot in real time.

Modular Design: Enables flexible configuration and easy upgrades, allowing manufacturers to scale operations as needed.

Automated Quality Control: Integrated sensors and vision systems detect defects instantly, ensuring only flawless bags reach the market.

Maintenance-Friendly Engineering: Accessible components and automatic lubrication systems reduce downtime and extend equipment lifespan.

Why Choose DESHENG for Your Paper Bag Production Needs?

When it comes to selecting the right automatic bottom gluing machine, DESHENG stands out as an industry leader. With a proven track record of innovation, DESHENG has developed China's first intelligent paper bag bottom pasting machine, setting new benchmarks for efficiency, quality, and reliability.

Key reasons to partner with DESHENG:

Cutting-Edge Technology: DESHENG machines feature servo intelligent systems, modular designs, and automatic adjustment capabilities, ensuring precise, high-speed production for a wide range of bag types and sizes.

Unmatched Efficiency: Fully automated processes minimize manual intervention, reduce downtime, and maximize output-helping you meet even the most demanding production schedules.

Superior Quality Control: Integrated inspection systems guarantee consistent, defect-free bags, enhancing your brand's reputation and customer satisfaction.

Comprehensive Support: From initial consultation to after-sales service, DESHENG provides expert guidance and technical support, ensuring your production line runs smoothly at all times.

Sustainability Focus: DESHENG's machines are designed for eco-friendly materials and processes, helping your business align with global environmental standards.

Whether you're upgrading outdated equipment or launching a new packaging line, DESHENG's advanced solutions will empower you to stay ahead in a competitive market. Choose DESHENG-your trusted partner for efficient, high-quality paper bag production.

Conclusion

Automatic bottom gluing machines have revolutionized the paper bag industry, transforming a once labor-intensive, inconsistent process into a model of modern manufacturing excellence. By automating every critical step-from feeding and folding to gluing, inspection, and stacking-these machines deliver unmatched efficiency, quality, and scalability.

As the demand for sustainable, high-performance packaging continues to grow, investing in state-of-the-art equipment like DESHENG's automatic bottom gluing machines is not just a smart business decision-it's a strategic move that positions your operation for long-term success. With the right technology and a trusted partner, your paper bag production can achieve new heights of productivity, reliability, and environmental responsibility.