In the rapidly evolving world of industrial packaging, automation has become a critical driver of efficiency, product quality, and cost-effectiveness. For businesses dealing with bulk solids or powders—such as cement, chemicals, minerals, or food ingredients—the adoption of an automatic valve bag packing machine can be transformative. However, with a wide array of models and features on the market, selecting the best machine for your unique needs can be a complex process. This article will guide you through the essential considerations, empowering you to make an informed decision that supports your production goals and business growth.

Understanding Automatic Valve Bag Packing Machines

An automatic valve bag packing machine is engineered to fill valve-type bags with powders, granules, or small aggregates. The valve bag design allows for fast, dust-free filling and secure, tamper-evident sealing. These machines are widely used in industries where hygiene, speed, and product integrity are paramount. The right machine can dramatically increase throughput, reduce labor costs, and ensure consistent product quality.

Key Considerations When Selecting an Automatic Valve Bag Packing Machine

1. Analyze Your Product Characteristics

The first step in choosing the right packing machine is to thoroughly understand the physical properties of your product. Is it a fine powder, a granular material, or a mixture with varying particle sizes? The flowability, density, and moisture content of your product will determine the type of filling system you need. For example, free-flowing powders may require air filling systems, while sticky or cohesive materials might need auger or impeller-based systems. Discuss your product's characteristics with potential suppliers to ensure compatibility and optimal performance.

2. Define Your Production Requirements

Every business has unique production targets. Consider your current and anticipated future output. How many bags do you need to fill per hour or per shift? Automatic valve bag packing machines come in various capacities, from moderate-speed units suitable for small to medium enterprises to high-speed systems designed for large-scale industrial operations. Choose a machine that not only meets your present needs but also allows for future scalability as your business grows.

3. Evaluate Bag Specifications

Valve bags are available in different sizes and materials, including paper, plastic, and woven polypropylene. Make sure the machine you select can handle your preferred bag type and size range. Some machines offer adjustable settings to accommodate a variety of bag dimensions, which is especially useful if you package multiple products or sizes. Additionally, consider the sealing method—ultrasonic, heat, or mechanical—based on your product's requirements and industry standards.

4. Assess Automation Level

The degree of automation you require will depend on your operational setup and labor considerations. Semi-automatic machines may require manual placement of bags, while fully automatic systems can handle bag placement, filling, sealing, and even palletizing with minimal human intervention. While fully automated solutions typically involve a higher initial investment, they can deliver significant savings in labor costs and improve overall efficiency in the long run.

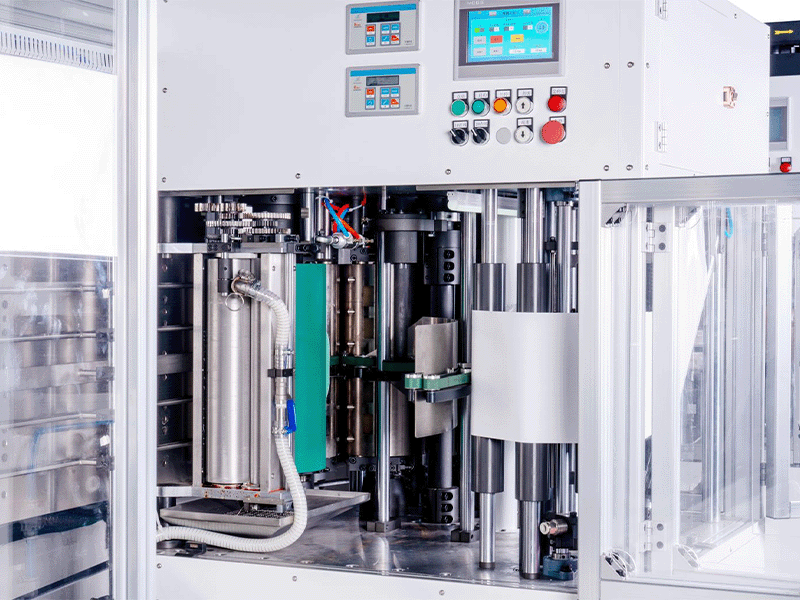

5. Prioritize Accuracy and Consistency

For businesses where products are sold by weight, weighing accuracy is critical. Modern automatic valve bag packing machines are equipped with advanced weighing controls, real-time monitoring, and automatic calibration features to ensure each bag is filled to the correct specification. Consistency in fill weights not only ensures compliance with regulations but also enhances customer satisfaction and trust in your brand.

6. Focus on Dust Control and Environmental Compliance

Many bulk powders generate dust during the filling process, which can pose health risks to workers and lead to product loss. Look for machines with effective dust control features, such as enclosed filling spouts and integrated dust extraction systems. Ensuring compliance with local environmental regulations is not just a legal obligation—it also demonstrates your commitment to workplace safety and environmental responsibility.

7. Consider Maintenance and Reliability

Downtime due to equipment failure can be costly. Invest in a machine known for its durability, reliability, and ease of maintenance. Check that spare parts are readily available and that the manufacturer offers comprehensive support services. A robust after-sales support network is essential for minimizing downtime and keeping your operations running smoothly.

8. Examine Integration Capabilities

If you already have an existing production line, consider how easily the new packing machine can be integrated into your workflow. Look for machines with flexible interfaces and compatibility with upstream and downstream equipment, such as conveyors, palletizers, and wrapping systems. Seamless integration will help you maximize the benefits of automation and avoid bottlenecks in your production process.

9. Calculate the Total Cost of Ownership

While the upfront cost of an automatic valve bag packing machine is an important consideration, it's equally important to evaluate the total cost of ownership. Factor in maintenance, energy consumption, spare parts, and potential savings from reduced labor and product loss. Often, a higher-quality machine with a greater initial investment will deliver better long-term value through improved efficiency and lower operating costs.

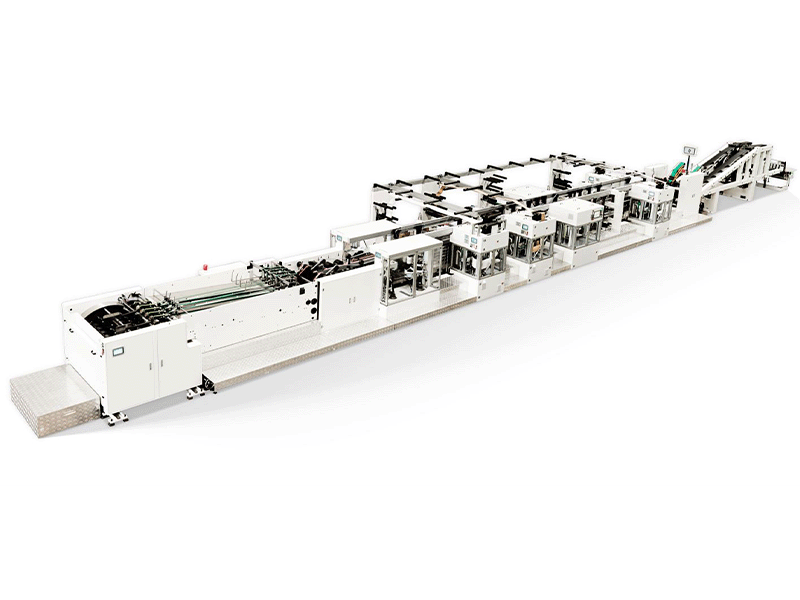

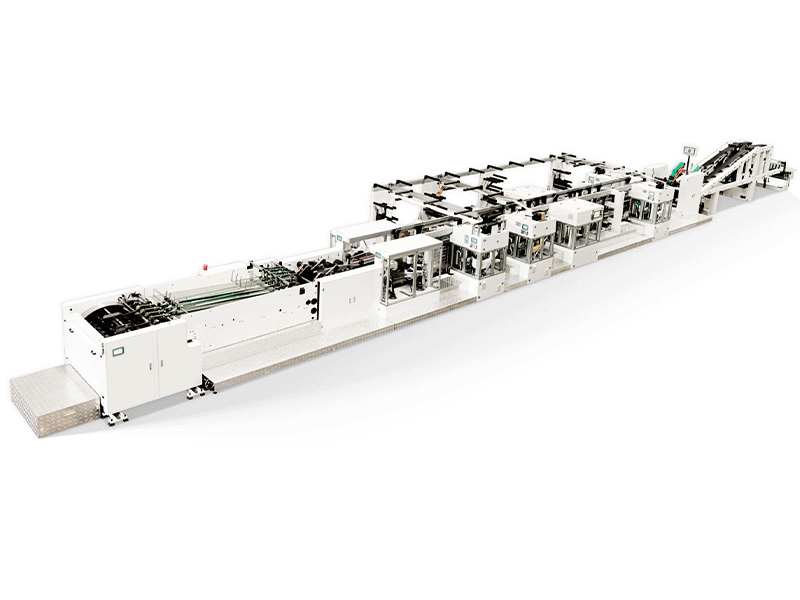

Why DESHENG is the Ideal Partner for Your Packing Automation Needs

When it comes to investing in an automatic valve bag packing machine, choosing the right supplier is just as crucial as selecting the right equipment. DESHENG stands out as a packing machine leader in the field, offering state-of-the-art solutions tailored to your specific needs.

DESHENG combines cutting-edge technology with a deep understanding of industry challenges. Our machines are equipped with advanced weighing and control systems, ensuring precise and consistent filling for a wide range of materials. We prioritize dust control and environmental compliance, helping you maintain a safe and clean workplace. Our flexible designs accommodate various bag types and sizes, making them suitable for diverse applications.

What truly sets DESHENG apart is our commitment to customer success. We offer comprehensive support from initial consultation through installation, operator training, and ongoing technical assistance. Our global reputation is built on reliability, innovation, and a partnership approach that puts your business goals first.

If you are looking for a automatic packing solution that delivers performance, reliability, and long-term value, DESHENG is your trusted partner. Visit our official website to learn more or contact our team for a personalized consultation.

Conclusion

Selecting the best automatic valve bag packing machine for your business is a strategic investment that can drive productivity, enhance product quality, and improve your bottom line. By carefully analyzing your product characteristics, production requirements, bag specifications, automation needs, and supplier reputation, you can make a choice that supports both your immediate and long-term goals.

Remember, the right machine is more than just a piece of equipment—it's a cornerstone of your operational success. Partnering with a reputable supplier like DESHENG ensures you receive not only a high-performance machine but also the expertise and support needed to optimize your packaging operations for years to come. Take the next step toward smarter, more efficient packaging by consulting with industry experts and investing in technology that grows with your business.