Industrial packaging in 2025 is experiencing a profound transformation, with valve bag making machines playing a pivotal role in this evolution. As industries face increasing demands for efficiency, product safety, and environmental responsibility, these advanced machines have become essential for packaging powders, granules, and other dry bulk materials. Their integration into modern production lines is reshaping how manufacturers approach packaging, offering new levels of precision, flexibility, and sustainability.

1. The Role and Working Principle of Valve Bag Making Machines

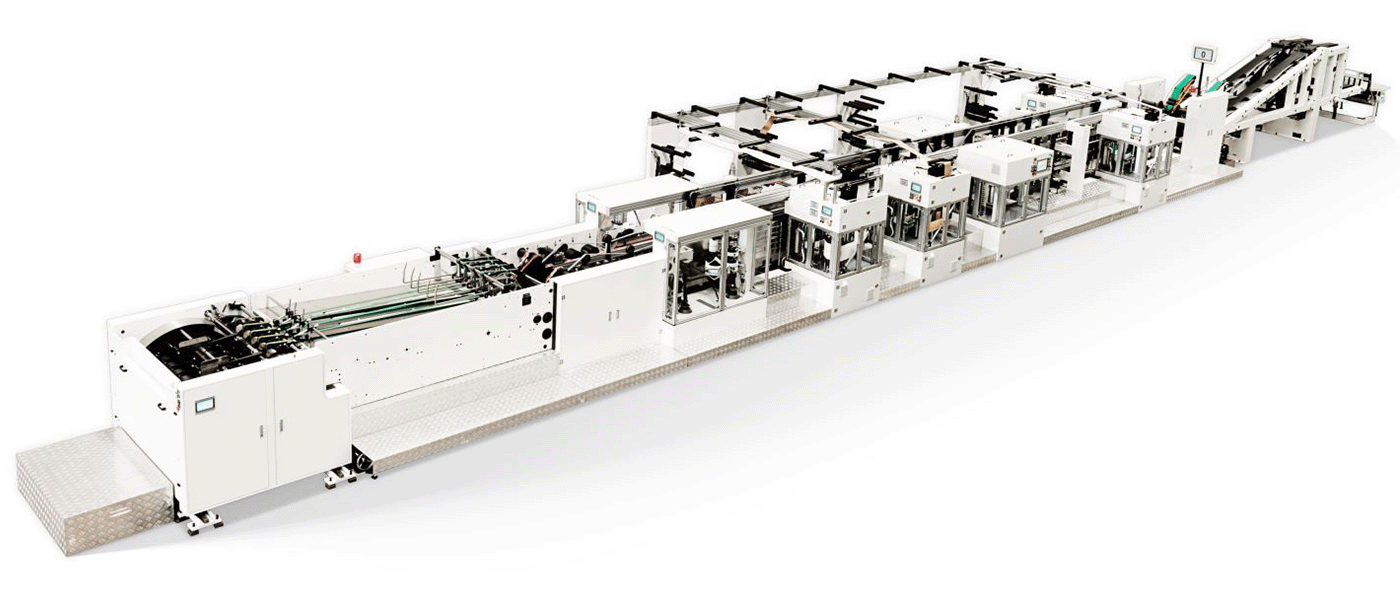

Valve bag making machines are specialized systems designed to automate the creation of valve bags—bags featuring a unique self-sealing valve for rapid, clean filling. The process begins with feeding large rolls of raw material, such as paper, plastic, or composite films, into the machine. Through a series of automated steps, the material is cut, folded, and formed into bags with precise dimensions. The valve mechanism is then integrated, allowing for efficient filling and secure closure.

This automated workflow eliminates the inconsistencies and inefficiencies of manual bag production. By ensuring each bag is produced to exact specifications, manufacturers can maintain high quality standards and minimize product loss. The self-sealing valve design is particularly valuable for industries where dust control and product containment are critical, such as food processing, chemicals, and construction materials.

2. Innovations Shaping the 2025 Packaging Landscape

Automation and Smart Integration

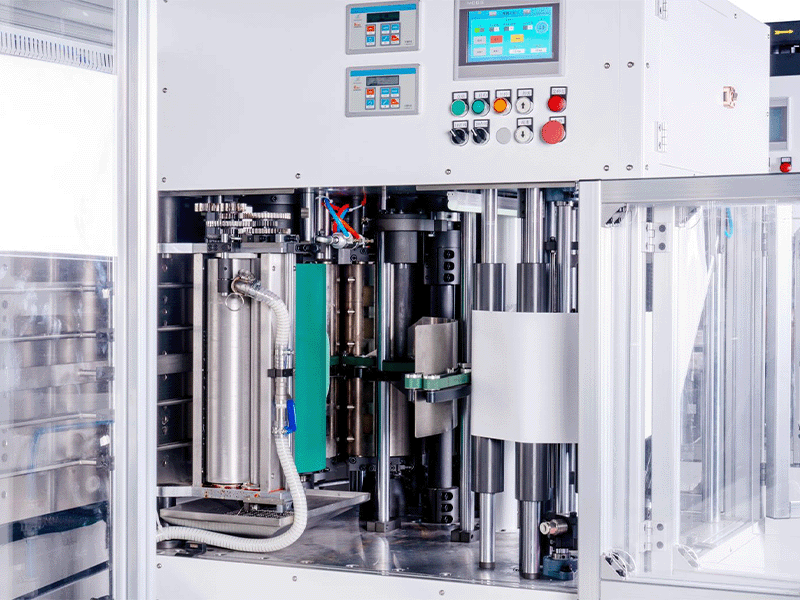

The latest generation of valve bag making machines is defined by advanced automation. These machines are equipped with intelligent control systems that synchronize seamlessly with upstream and downstream equipment, including filling stations, conveyors, and palletizers. This integration enables a continuous, high-speed packaging process with minimal human intervention. Features like real-time monitoring, automatic fault detection, and remote diagnostics further enhance operational reliability and efficiency.

Material Adaptability and Customization

Modern valve bag machines are engineered for versatility. They can process a wide range of materials—including recyclable plastics, biodegradable papers, and woven fabrics—giving manufacturers the flexibility to choose packaging solutions that align with their product requirements and sustainability goals. This adaptability is crucial as industries face evolving regulations and consumer expectations regarding eco-friendly packaging.

Precision Engineering and Product Quality

Digital controls and advanced sensors ensure that every bag produced meets stringent quality standards. The machines can be finely adjusted to accommodate different bag sizes, thicknesses, and valve placements, reducing material waste and optimizing storage efficiency. This level of precision is especially important for products that require airtight or moisture-resistant packaging, such as specialty chemicals or food ingredients.

3. Operational and Economic Advantages

Labor and Cost Efficiency

By automating the bag production process, valve bag making machines significantly reduce the need for manual labor. This not only lowers operational costs but also minimizes the risk of workplace injuries associated with repetitive tasks and heavy lifting. The ease of maintenance and rapid changeover capabilities further contribute to higher productivity and reduced downtime, allowing manufacturers to respond quickly to changing market demands.

Enhanced Product Protection and Hygiene

Valve bags produced by these machines offer superior protection against environmental factors such as moisture, dust, and contaminants. The hermetic sealing and robust construction ensure that products remain safe and intact throughout storage and transportation. This is particularly important for industries with strict hygiene requirements, such as food, pharmaceuticals, and agriculture.

Sustainability and Environmental Impact

Sustainability is a central focus for manufacturers in 2025. Valve bag making machines support this goal by enabling the use of recyclable and compostable materials, as well as lightweight designs that reduce raw material consumption. The precise filling and sealing processes minimize spillage and waste, helping companies lower their environmental footprint and comply with global sustainability standards.

4. Diverse Industry Applications

Valve bag making machines have found widespread application across multiple sectors:

Food and Agriculture: From flour and sugar to grains and animal feed, these machines ensure that products are packaged with maximum freshness and hygiene, meeting food safety regulations and consumer expectations.

Chemicals: For powders, fertilizers, and specialty chemicals, valve bags provide secure containment, reducing the risk of spills and exposure during handling and transport.

Construction Materials: Cement, adhesives, and other building materials benefit from the tear-resistant and weatherproof qualities of valve bags, which maintain product integrity even in demanding environments.

The versatility of valve bag making machines allows manufacturers to tailor packaging solutions to the unique needs of each industry, ensuring optimal performance and compliance.

5. Future Trends: Smart Manufacturing and Digitalization

Looking ahead, the evolution of valve bag making machines is closely linked to the rise of smart manufacturing. IoT-enabled systems are becoming standard, offering features such as predictive maintenance, energy consumption analytics, and real-time production monitoring. Artificial intelligence is being integrated to optimize process parameters, enhance quality control, and further reduce operational costs.

Manufacturers are also exploring new materials and energy-efficient technologies, such as solar-powered operations and biodegradable films, to meet the growing demand for sustainable packaging. These innovations position valve bag making machines as key drivers of industrial progress and environmental responsibility.

Conclusion

Valve bag making machines have truly revolutionized industrial packaging in 2025. By combining speed, precision, and sustainability, they empower manufacturers to achieve higher productivity, superior product protection, and compliance with global environmental standards. As industries continue to evolve, the importance of reliable, innovative packaging solutions will only grow.

For businesses seeking to stay ahead in this competitive landscape, choosing the right partner is essential. DESHENG stands out as a trusted valve bag making machine supplier, offering advanced valve bag making machines that deliver exceptional performance and adaptability. With a commitment to quality, efficiency, and eco-friendly design, DESHENG helps manufacturers optimize their packaging lines and achieve long-term success. If you are considering upgrading your packaging operations, exploring DESHENG's solutions is a strategic step toward a more efficient and sustainable future.