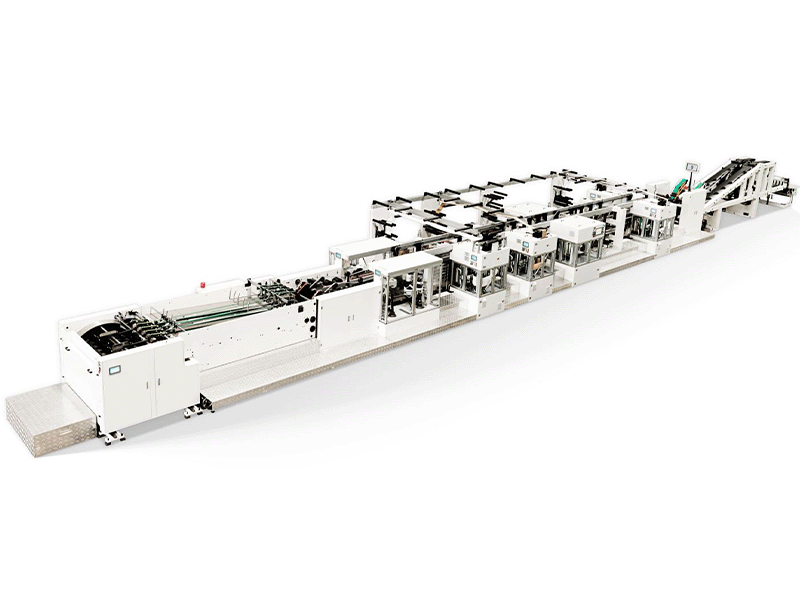

The packaging industry is evolving rapidly, driven by the need for higher efficiency, sustainability, and consistent quality. Valve bag packaging machines remain essential for industries such as cement, flour, chemicals, and food. In 2025, technological advancements are helping manufacturers achieve better performance, reduced waste, and smoother production. Understanding these innovations can help you choose the right machine for your packaging line and stay competitive in a fast-moving market.

Valve bag machines are more than just tools to form and seal bags—they are integral to your production efficiency, product protection, and overall operational costs. Let's explore the most significant innovations shaping valve bag packaging machines in 2025, from automation to digital integration.

1. Advanced Automation and Control Systems

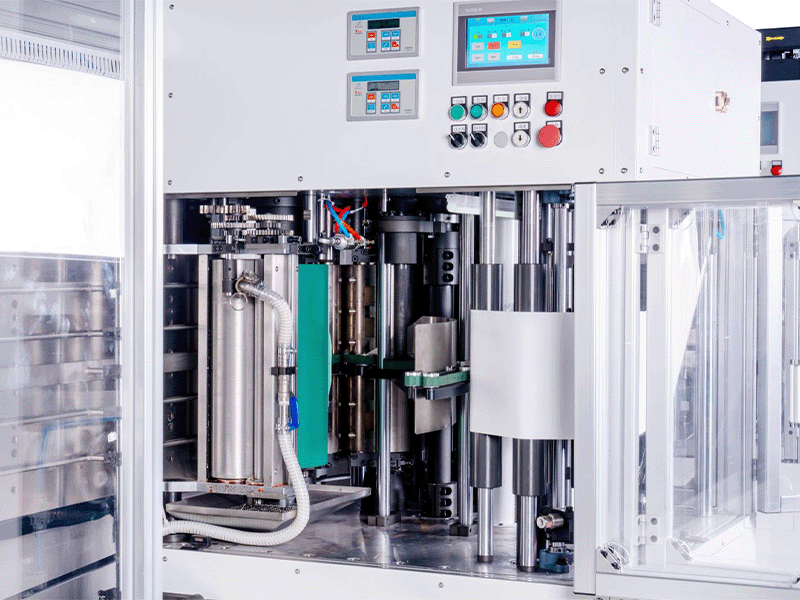

Automation continues to be a major trend in industrial packaging. Modern valve bag machines are increasingly equipped with PLC (Programmable Logic Controller) systems, touchscreen interfaces, and automated monitoring capabilities. These systems allow precise control over bag formation, valve placement, and production speed.

With advanced automation, machines can maintain consistent bag dimensions and placement accuracy at high speeds. This reduces errors, decreases material waste, and improves throughput. Automated monitoring also alerts operators to potential issues before they become production bottlenecks.

For companies looking for reliable, high-efficiency solutions, machines with advanced control systems provide a clear competitive advantage. Certain enhanced valve bag assembly machines, for example, allow operators to program multiple bag types and production sequences, reducing manual adjustments and saving time.

Key Benefits of Advanced Automation:

- Consistent bag quality across large production volumes

- Reduced human errors and operational mistakes

- Higher throughput and production scalability

2. Energy Efficiency and Eco-Friendly Designs

Sustainability has become a key consideration for manufacturers worldwide. In 2025, many valve bag packaging machines are designed with energy-efficient motors, optimized pneumatic systems, and materials that reduce energy consumption.

Energy-efficient designs not only reduce electricity costs but also help companies comply with environmental regulations. Some machines even include standby modes for idle periods and automated power management systems to minimize energy waste.

Manufacturers are also exploring lighter yet durable components that maintain machine stability while lowering overall energy requirements. Eco-friendly designs help companies reduce their carbon footprint and promote sustainability initiatives, which can be an important factor for corporate responsibility and customer perception.

Why Energy Efficiency Matters:

- Lower operational costs over the machine's lifetime

- Compliance with increasingly strict environmental regulations

- Positive brand image and market perception

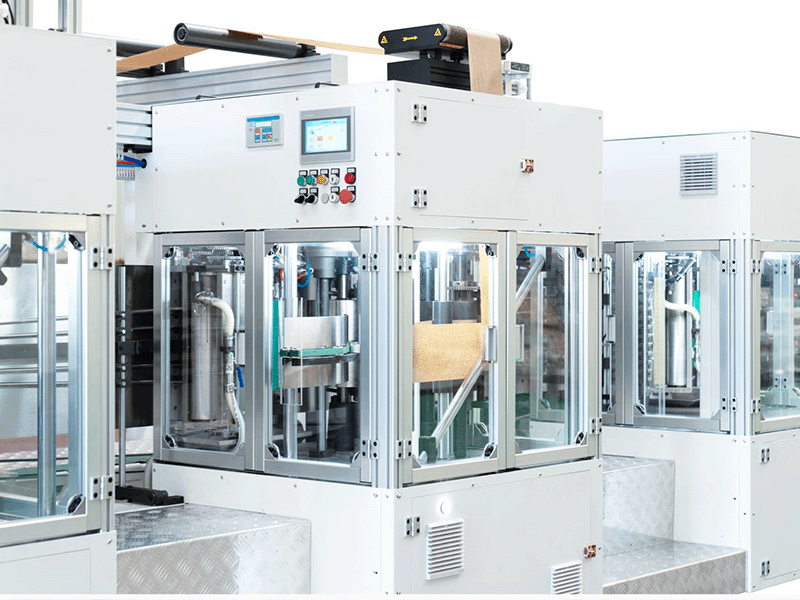

3. Enhanced Precision and Quality Control

High-quality bag formation is critical for protecting products and maintaining brand reputation. Innovations in precision engineering, including servo-driven mechanisms and smart sensors, now allow real-time monitoring of bag dimensions, valve placement, and sealing integrity.

These features significantly reduce defective bags, minimize material waste, and improve overall production reliability. Consistent bag quality is particularly important for industries handling fine powders, chemicals, or food products, where minor errors can lead to product loss or contamination.

Some modern machines incorporate automated valve alignment systems that adjust dynamically to different bag sizes and materials. This allows manufacturers to run multiple production batches with minimal downtime and reduces the need for manual intervention.

Benefits of Enhanced Precision:

- Uniform bag size and shape

- Reduced risk of leaks or spills

- Optimized material usage and lower waste

4. User-Friendly Interfaces and Remote Monitoring

Ease of operation is a key factor in minimizing downtime and improving productivity. Modern valve bag machines are now equipped with intuitive touchscreens, simple navigation menus, and automated parameter settings. Operators can easily adjust bag dimensions, speed, and valve placement without extensive training.

Remote monitoring is another significant innovation. Some machines can be connected to cloud-based platforms, allowing managers to track performance, receive alerts for maintenance, and log production data in real time. These capabilities help operators make informed decisions and plan preventive maintenance, reducing unplanned stoppages.

Machines designed with user-friendly operation also improve safety. Clear displays, automated error warnings, and easy access to components reduce the risk of operator mistakes or injury during routine use.

5. Flexibility and Multi-Purpose Capabilities

The market demands versatility, and 2025 valve bag machines are designed with flexibility in mind. Modern machines can handle a wide range of bag sizes, paper weights, and valve types, reducing the need for multiple specialized machines.

Flexible machines allow manufacturers to switch between products quickly, meeting changing customer demands without significant downtime. This adaptability is particularly valuable for businesses with seasonal production shifts or those exploring new markets.

Investing in versatile equipment ensures that your packaging line can evolve alongside your business. Machines capable of handling multiple materials and bag formats also help maximize return on investment.

6. Integration with Digital Supply Chain Systems

Another emerging trend is connectivity. Modern valve bag machines increasingly integrate with digital supply chain platforms to optimize inventory management, scheduling, and logistics.

Connected machines can provide real-time production data, automated reporting, and analytics that improve decision-making. By linking packaging equipment to broader operational systems, manufacturers can identify inefficiencies, reduce bottlenecks, and better coordinate with suppliers and warehouses.

Digital integration enhances visibility across the production line and allows companies to proactively respond to changes in demand or production issues. This level of control supports lean manufacturing and reduces operational risk.

7. Optional Enhancements and Specialized Features

Many manufacturers are now offering optional enhancements, such as:

- Anti-dust or anti-static features for sensitive materials

- Automatic gluing and sealing systems for faster operations

- Customizable programming for different bag types or sizes

These options allow businesses to tailor machines to their specific needs, increasing efficiency and reducing operational challenges.

Conclusion

Valve bag packaging machines in 2025 are smarter, more efficient, and more adaptable than ever. Key innovations—including automation, energy efficiency, precision, user-friendly operation, flexibility, and digital integration—are transforming the way companies package their products.

For businesses looking for reliable solutions with a balance of modern technology and proven performance, DESHENG offers a range of valve bag forming machines designed to meet diverse production needs. By choosing equipment that incorporates these innovations, manufacturers can improve efficiency, reduce waste, and maintain high-quality packaging standards.