In today's competitive packaging industry, businesses are under pressure to maximize efficiency, reduce costs, and deliver consistently high-quality products. For many manufacturers, especially in industries like cement, chemicals, flour, minerals, and food, valve bag machines are essential for meeting production and market demands.

However, when choosing between a standard valve bag machine and a reinforced valve bag machine, many decision-makers struggle to identify which solution best aligns with their production needs. Both machines serve similar functions but differ in strength, versatility, cost-effectiveness, and application suitability.

This article provides a detailed comparison of standard vs reinforced valve bag machines, helping you make an informed decision.

Understanding Standard Valve Bag Machines

A standard valve bag forming machine is designed for most general-purpose packaging applications. It forms and glues valve paper bags with precision, creating a reliable product suitable for industries handling powders and granules.

Key Features of Standard Machines:

Efficient production speed – suitable for high-volume bag production.

Consistent bag quality – ensures reliable sealing and easy filling.

Cost-effective investment – lower initial purchase and operational costs.

Suitable for lighter to medium loads – ideal for flour, animal feed, fertilizers, and other non-abrasive materials.

For companies with stable, large-scale production, the standard valve bag machine offers a strong balance between affordability and performance.

Understanding Reinforced Valve Bag Machines

By contrast, a reinforced valve bag machine is designed for heavier-duty applications where strength and durability are critical. These machines add extra layers of reinforcement during the bag-forming process, making bags more resistant to tearing, moisture, and rough handling.

Key Features of Reinforced Machines:

Extra durability and strength – ideal for abrasive or heavy products like cement, minerals, or construction materials.

Customizable reinforcement options – additional paper layers or advanced adhesives.

Higher load capacity – suitable for products requiring strong packaging integrity.

Enhanced sealing technology – reduces leakage and spillage during filling, transportation, and storage.

Reinforced valve bag machines cater to industries where packaging must withstand extreme stress and environmental conditions.

Cost Comparison: Standard vs Reinforced

One of the most important considerations for any buyer is cost.

Standard Valve Bag Machine:

- Lower purchase price

- Lower energy consumption and maintenance costs

Suited for companies with limited budgets or those packaging less demanding products

Reinforced Valve Bag Machine:

- Higher initial investment

- Slightly higher energy use due to additional reinforcement steps

- Longer-lasting bags reduce product loss, potentially saving money in the long term

Verdict: If your products require only moderate packaging, a standard machine is the economical choice. However, for industries where bag failure could lead to major financial loss, investing in a reinforced system is more cost-effective over time.

Production Efficiency and Speed

Standard Machines: Typically faster due to fewer reinforcement steps. They are ideal for companies prioritizing high-speed mass production.

Reinforced Machines: Slightly slower but offer higher reliability and durability. These machines are better suited for quality-focused industries.

Quality and Application Differences

Standard Valve Bags: Perfect for flour, starch, food ingredients, animal feed, and similar products that don't exert high stress on the packaging.

Reinforced Valve Bags: Designed for cement, chemicals, minerals, and heavy powders where durability and leakage prevention are essential.

In practice, many businesses use a combination of both depending on customer requirements and market needs.

Maintenance and Longevity

Standard Machines: Easier and cheaper to maintain. Components are straightforward, and downtime is usually minimal.

Reinforced Machines: Require more frequent monitoring due to the complexity of reinforcement mechanisms but are built for heavy-duty, long-term operation.

Choosing the Right Machine for Your Business

When deciding between a standard valve bag machine and a reinforced valve bag machine, you should evaluate:

Product Type – Is your product lightweight or heavy, abrasive, or moisture-sensitive?

Production Volume – Do you prioritize speed or packaging strength?

Budget – Are you focused on upfront cost savings or long-term durability?

Customer Expectations – Do your customers require heavy-duty bags for transportation and storage?

For example:

- A flour mill may choose a standard valve bag machine for cost-effective, high-speed packaging.

- A cement manufacturer, on the other hand, would rely on a reinforced valve bag machine to prevent leakage and withstand rough handling.

Why DESHENG?

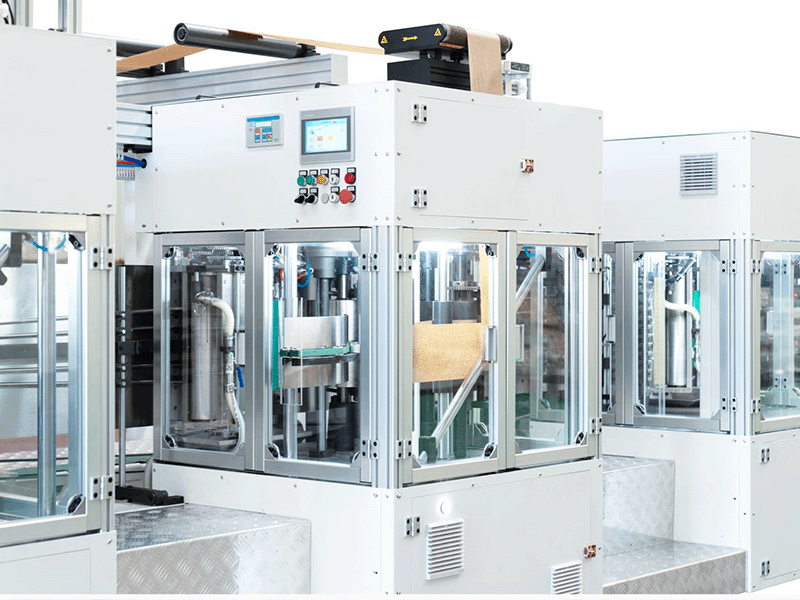

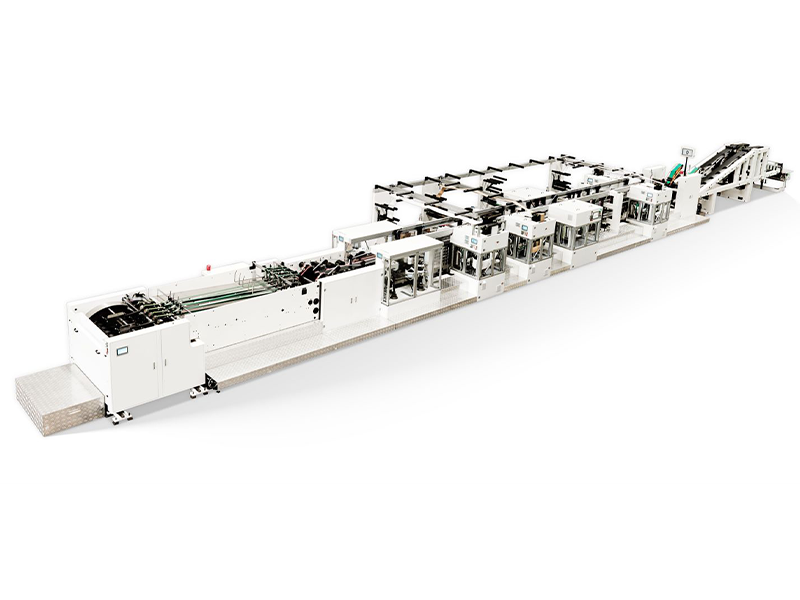

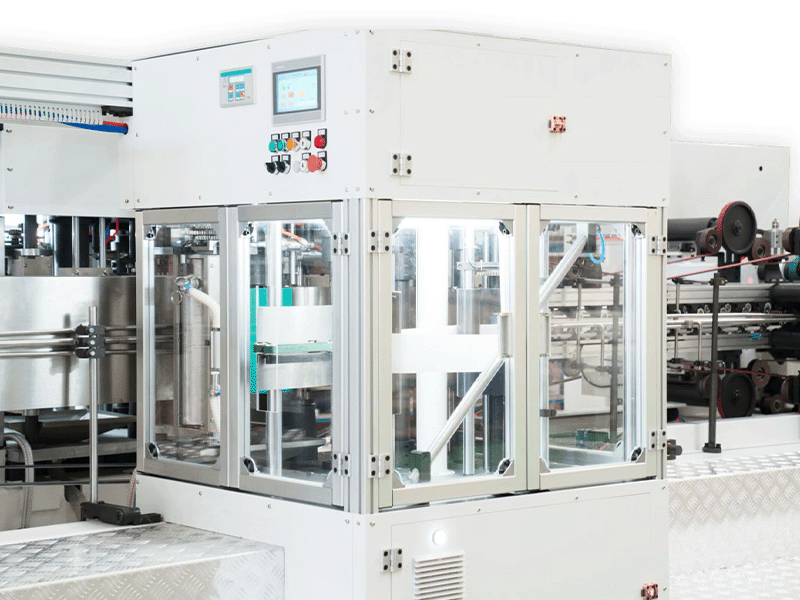

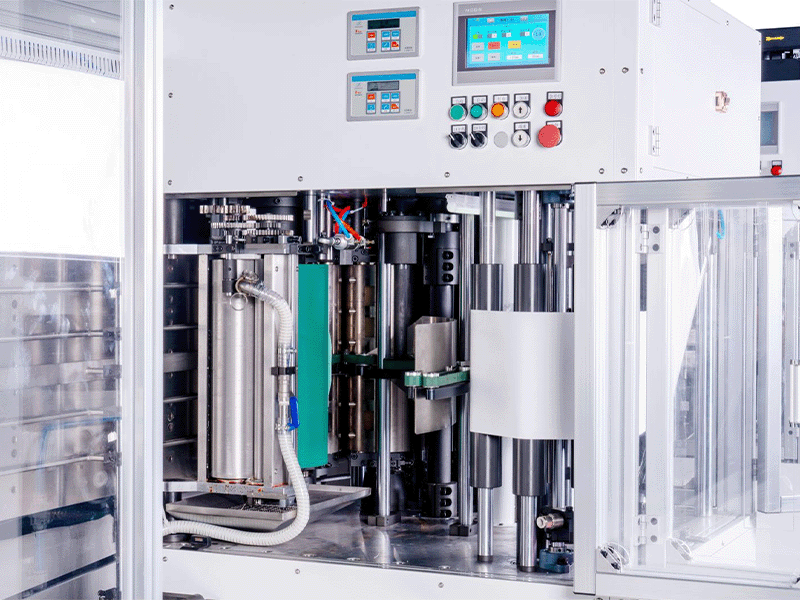

As a manufacturer specializing in valve bag machines, DESHENG understands that every production line has unique requirements. Our product range includes:

- Standard Valve Bag Forming Machines – for cost-effective, high-speed packaging.

- Reinforced Valve Bag Manufacturing Machines – for heavy-duty, durable, and reliable packaging solutions.

With years of expertise, DESHENG machines are engineered for efficiency, precision, and durability. Whether your business requires high-volume output or robust packaging for demanding industries, our solutions are designed to help you meet your goals.

Conclusion

The choice between standard vs reinforced valve bag machines ultimately depends on your product type, production demands, and budget priorities. Standard machines offer speed and affordability, while reinforced machines ensure durability and reliability for heavy-duty applications.

By carefully evaluating your needs, you can select the machine that ensures maximum efficiency, minimum waste, and consistent product quality. For businesses seeking advanced and reliable solutions, DESHENG provides both standard and reinforced valve bag machines tailored to meet diverse industrial demands.