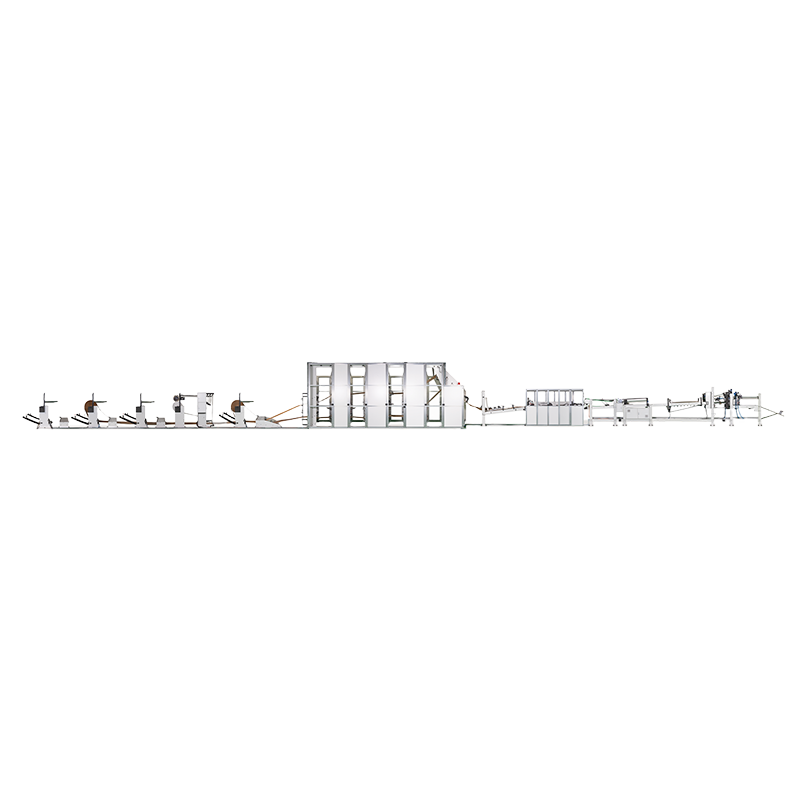

In today's industrial packaging industry, efficiency and quality are more important than ever. Paper valve bags are widely used for cement, agricultural products, activated carbon, and other granular materials. To keep up with growing production demands, upgrading to a high-speed intelligent tube forming machine is a crucial step for modern manufacturers. Our DESHENG tube forming machine combines speed, precision, and automation to streamline your production line.

Here are the top five reasons why upgrading to this machine can transform your operations.

1. Significantly Improve Production Efficiency

Automated Operation

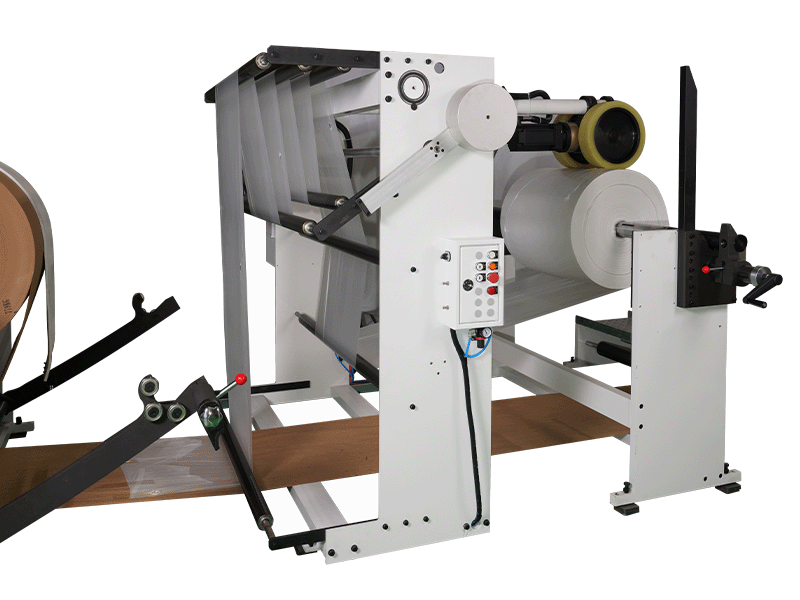

Manual and semi-automatic tube forming systems often require operators to handle paper feeding, cutting, and tube formation. This slows down the production process and increases the risk of errors. With our high-speed intelligent tube forming machine, these tasks are automated. The machine continuously feeds, cuts, and forms tubes without constant human intervention, allowing production to run smoothly and efficiently.

Stable Output

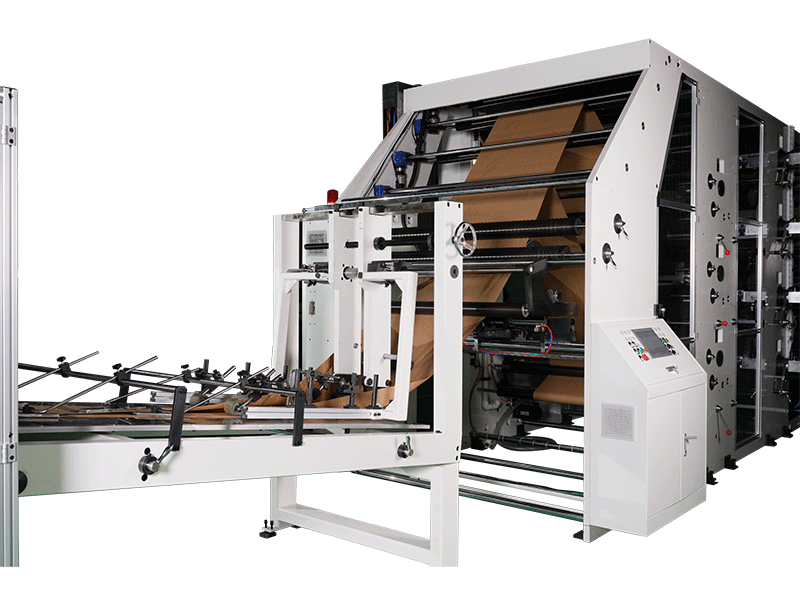

Consistency in production is critical for large-scale operations. Our machine maintains stable output throughout the shift, minimizing pauses or delays. The integration with our valve bag base machine ensures the workflow remains continuous, reducing downtime and increasing overall productivity.

Easy Workflow Management

Operators can monitor the machine through a user-friendly interface, adjusting parameters when necessary without stopping the line. This feature allows you to maintain a high production pace while keeping the process under control.

2. Ensure Consistent Product Quality

Precise Tube Formation

A high-speed intelligent tube forming machine ensures that each paper tube is uniform in size and shape. Servo-controlled motors guide the paper accurately, maintaining precise dimensions and alignment.

Accurate Glue Application

Glue placement is one of the most important aspects of valve bag production. Uneven glue can cause weak seals or bag deformation. Our machine uses intelligent glue application technology to guarantee strong, reliable seals every time.

Reduced Defects

Automation reduces human error. In traditional manual systems, inconsistencies in feeding, folding, or sealing often lead to rejected products. By automating these critical steps, our DESHENG machine minimizes defects and maintains high-quality output, protecting your brand reputation and reducing material waste.

3. Lower Labor Requirements and Minimize Human Error

Reduce Operator Dependency

Manual machines require operators to be present for almost every step of production. Our intelligent tube forming machine reduces the need for constant supervision. Operators mainly monitor the machine and manage material supply, allowing your workforce to focus on other tasks.

Safer Working Environment

With fewer manual tasks, operators are less exposed to moving parts or heated components, creating a safer work environment.

Minimize Errors and Waste

Automation prevents mistakes like misalignment, incorrect cutting, or uneven sealing, which are common in manual production. By reducing these errors, the machine not only improves output consistency but also lowers production costs.

4. Seamless Integration into Automated Production Lines

Smart Connectivity

Our high-speed tube forming machine is designed to integrate smoothly with other equipment, including valve bag base machines and packaging lines. Smart connectivity allows for real-time communication between machines, synchronizing speed and operations.

Real-Time Adjustments

Built-in sensors monitor performance and adjust parameters automatically to maintain product consistency. For example, if the paper feed slightly deviates, the machine corrects it immediately, ensuring each tube meets the required standards.

End-to-End Automation

With automated feeding, forming, gluing, and base assembly, your production line becomes more efficient and predictable. Integration reduces idle time and simplifies workflow, helping your plant achieve continuous high-speed operation.

5. Optimize Costs and Support Sustainability

Reduce Material Waste

Accurate paper feeding and glue application reduce waste caused by misalignment or overuse. This efficiency lowers overall material costs while supporting sustainable manufacturing practices.

Energy Efficiency

Our machine is designed to optimize energy use. Components are engineered for high efficiency, ensuring that production consumes less power compared to older or manual systems.

Durable Design

Built with reliability in mind, the high-speed intelligent tube forming machine requires minimal maintenance and has a long operational life. Regular preventive maintenance is simple, allowing your line to run smoothly for years.

Upgrading not only improves efficiency but also helps achieve long-term cost savings while aligning with environmentally responsible practices.

Why Upgrade With DESHENG

At DESHENG, we focus on developing intelligent, high-speed tube forming machines that meet the evolving needs of modern manufacturers. Our packing machines are engineered for precision, speed, and durability, with user-friendly control systems that simplify operation.

We also provide technical support and guidance for integration, ensuring that your production line achieves maximum efficiency and consistent product quality. Upgrading with DESHENG means gaining a reliable partner who understands the challenges of industrial packaging and helps you achieve sustainable growth.

Conclusion

Upgrading to a high-speed intelligent tube forming machine is a strategic investment for any manufacturer of paper valve bags. It improves production efficiency, ensures consistent quality, reduces labor requirements, and supports sustainable operations. By integrating our DESHENG machine into your production line, you can enhance performance, lower costs, and maintain a competitive edge in the industrial packaging market.