In today's packaging industry, efficiency and accuracy are no longer optional—they are essential. Valve bag forming machines are at the heart of industrial packaging, especially for products like cement, flour, chemicals, and construction materials. A poorly chosen machine can slow down production, increase downtime, and reduce profit margins. On the other hand, selecting the right valve bag forming machine ensures smooth operations, consistent product quality, and long-term savings.

With so many options available on the market, it can be difficult to know what to prioritize. To help you make an informed decision, this article highlights the top 5 features you should look for in a valve bag forming machine. These features not only determine the efficiency of your packaging line but also influence your overall operational costs.

1. High Precision and Consistent Bag Formation

The first and most important feature is precision. A valve bag forming machine must be able to produce bags with accurate dimensions, neat folds, and precise valve placement. Inconsistent bag quality can lead to problems during filling, sealing, and shipping.

For industries handling powders or bulk goods, a poorly formed bag may leak, tear, or fail during transportation—leading to wasted materials and unhappy customers. That's why a machine with advanced control systems and reliable forming technology is critical.

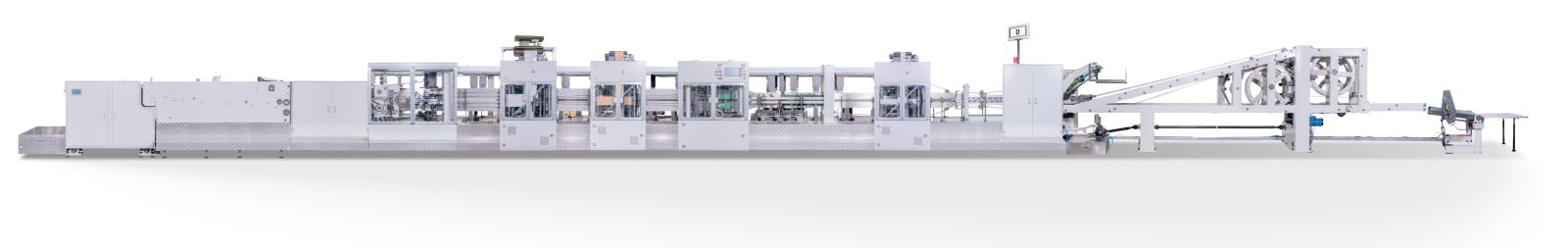

At DESHENG, our Standard Valve Bag Forming Machines are engineered to deliver consistent results, even at high speeds. Using precision-driven components and modern automation, they minimize errors and reduce waste, which directly improves your bottom line.

Key Benefits of Precision in Bag Formation:

- Reduced rejection rates

- Improved brand reputation through consistent packaging

- Lower material waste and higher efficiency

2. Adjustable Production Speed

Not all production runs are the same. Sometimes you need to push your machines to meet high demand; at other times, you may require slower speeds for specialized orders. That's why adjustable production speed is a must-have feature.

A high-quality valve bag forming machine should provide variable speed settings, giving manufacturers the flexibility to adapt to different bag types and production schedules. Machines that are either too slow or too rigid in operation can limit your business growth.

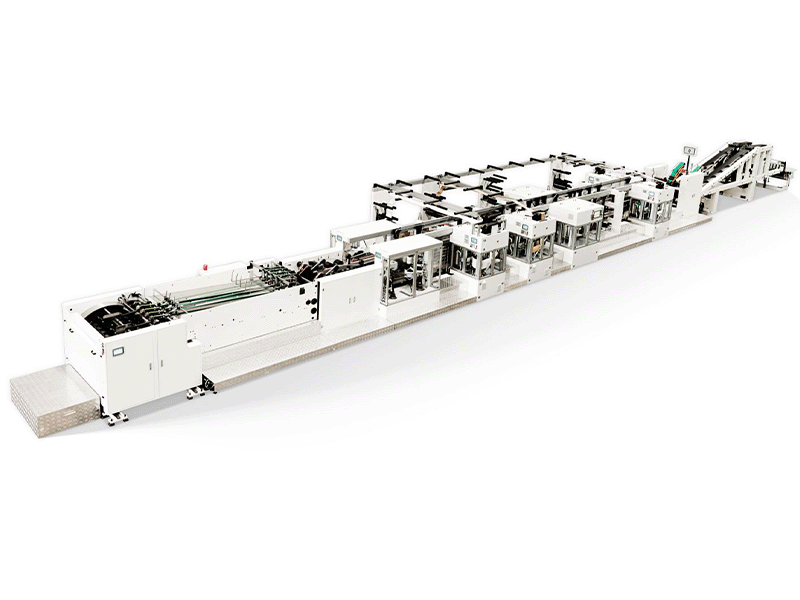

For example, DESHENG's Enhanced Type Valve Bag Assembly Machine allows users to fine-tune speed without compromising accuracy. This flexibility makes it ideal for both large-scale operations and smaller, customized production runs.

Why Adjustable Speed Matters:

- Boosts efficiency during peak demand

- Protects machine components by avoiding unnecessary strain

- Provides scalability for growing businesses

3. Durability and Build Quality

A valve bag forming machine is a long-term investment. Therefore, durability should always be a deciding factor. Machines that break down frequently or require constant repairs will increase downtime and inflate maintenance costs.

Look for machines constructed from high-grade materials, with reinforced frames and heavy-duty components that can withstand continuous operation. In addition, parts should be resistant to wear and corrosion, especially if the machine is used in dusty or humid environments.

DESHENG's Reinforced Valve Bag Manufacturing Machines are designed for heavy-duty packaging tasks. Built with solid, industrial-grade components, they provide stable performance even under demanding workloads. This reliability ensures your packaging line runs smoothly and efficiently for years.

Advantages of Durable Machines:

- Longer lifespan and higher return on investment

- Less frequent downtime and repairs

- Increased operator safety during production

4. User-Friendly Operation and Easy Maintenance

Complex machinery can slow down production if it requires highly skilled operators or constant technical support. That's why ease of use and maintenance-friendly design are important when selecting a valve bag forming machine.

Look for features such as:

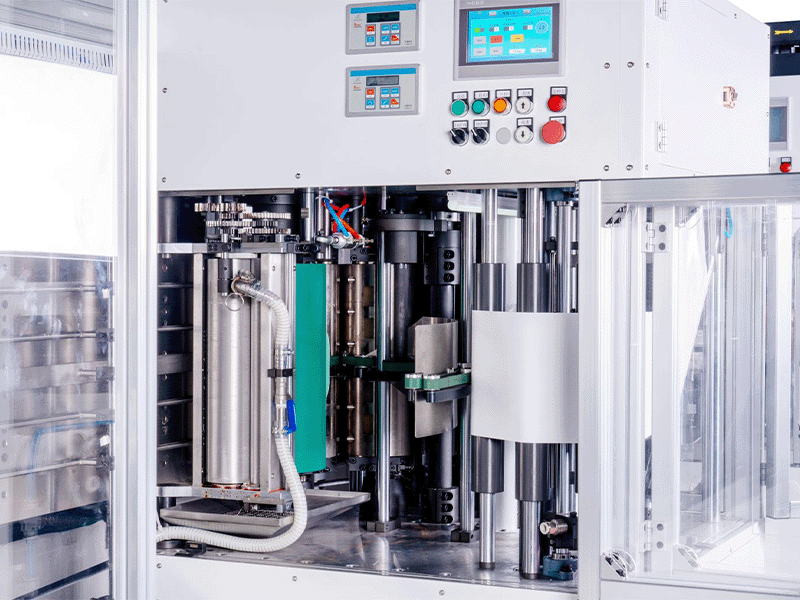

- Intuitive control panels (touchscreens preferred)

- Automated settings for bag size and valve placement

- Quick access to components for cleaning or replacement

- Built-in error detection and safety alarms

At DESHENG, our machines are designed with the operator in mind. The Standard Reinforced Valve Bag Manufacturing Machine features an intuitive interface that minimizes training time. Operators can monitor production, adjust parameters, and troubleshoot issues without needing specialized expertise.

By simplifying daily operations, user-friendly machines reduce the risk of human error and maximize productivity.

5. Flexibility and Compatibility with Different Bag Types

Markets evolve, and so do packaging requirements. Businesses that invest in rigid, single-purpose machines may find themselves limited in the future. Therefore, versatility is a vital feature to look for.

A good valve bag forming machine should handle various paper grades, bag sizes, and valve types, making it suitable for multiple industries. This adaptability ensures that your machine can keep up with changing product lines and customer demands.

For example, DESHENG's Enhanced Type Valve Bag Assembly Machine is built to accommodate a wide range of bag dimensions and materials. This flexibility reduces the need for separate machines, making it a cost-effective solution for expanding businesses.

Benefits of Flexibility in Packaging Machines:

- Ability to serve different industries (cement, food, chemicals, etc.)

- Lower investment compared to buying multiple machines

- Faster adaptation to market changes

Additional Considerations Beyond the Top 5

While the above five features are the most critical, buyers should also consider:

- Energy Efficiency: Machines that consume less power reduce operational costs.

- Safety Features: Emergency stop buttons, guards, and alarms protect operators.

- After-Sales Support: A reliable manufacturer should provide technical support, spare parts, and training.

When evaluating suppliers, it's important to consider not only the machine itself but also the company's track record. DESHENG has years of experience in manufacturing valve bag forming machines, offering reliable customer support and tailored solutions for businesses worldwide.

Conclusion

Choosing the right valve bag forming machine can dramatically improve efficiency, reduce waste, and increase profitability in your packaging operations. By focusing on precision, adjustable speed, durability, user-friendly operation, and flexibility, you'll ensure that your machine meets current needs while being adaptable to future demands.

For businesses seeking dependable solutions, DESHENG offers a wide range of valve bag forming machines, including standard, reinforced, and enhanced types. With robust construction, advanced automation, and proven reliability, DESHENG machines are trusted by industries worldwide to deliver high performance and long-term value.

If your goal is to enhance production capacity, reduce downtime, and achieve consistent bag quality, investing in a DESHENG valve bag forming machine could be the smartest decision for your business.