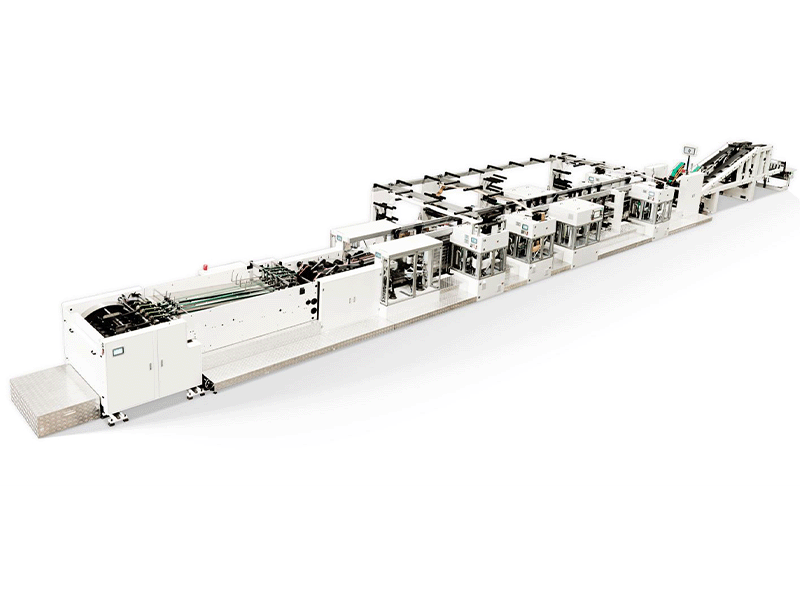

In today's competitive packaging industry, efficiency, precision, and reliability are crucial. As a company deeply involved in the manufacturing of industrial packaging machinery, at DESHENG, we understand the challenges faced by factories producing valve bags for cement, powders, chemicals, and other granular materials. In this guide, I'll walk you through a step-by-step overview of a valve bag production line, highlighting the machines, processes, and best practices that ensure high-quality output.

Step 1: Material Preparation

The foundation of a reliable valve bag production line starts with high-quality raw materials. Paper rolls used for valve bags must meet specific thickness and strength standards. At DESHENG, we recommend sourcing paper that can withstand the weight and pressure of heavy products, particularly for cement or powdered chemicals.

Key points:

- Use strong Kraft paper or multi-ply paper.

- Ensure paper moisture content is optimized for smooth processing.

- Inspect raw material for defects to prevent machine jams.

Step 2: Cutting and Folding

Once the paper is ready, the next stage is cutting and folding. Our DESHENG automatic valve bag machines are designed to accurately cut paper to the required length and fold it consistently to form the bag's basic structure. This stage sets the stage for precise bottom pasting and valve installation.

Key points:

- Use programmable cutting units for different bag sizes.

- Folding mechanisms must maintain uniformity across large production volumes.

- Regular calibration ensures consistent bag dimensions.

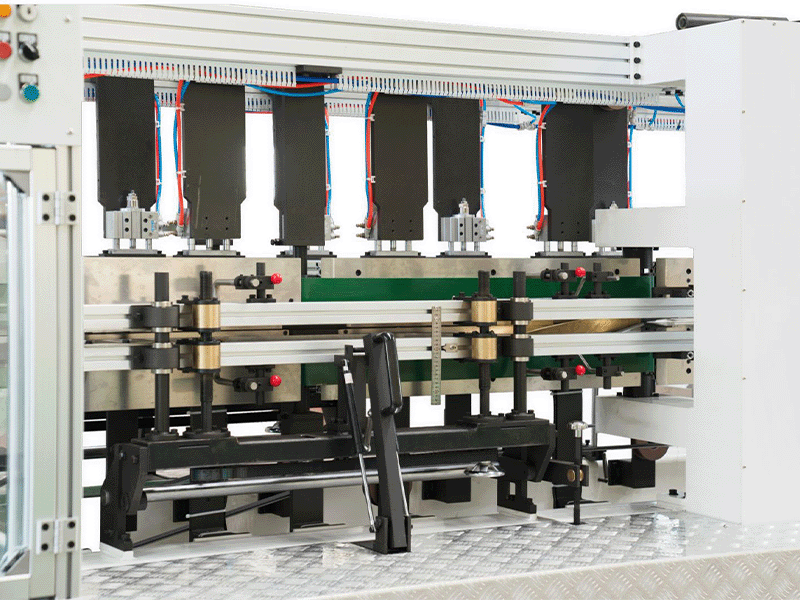

Step 3: Bottom Pasting

A crucial step in valve bag production is bottom pasting, which ensures the bag can securely hold heavy materials without tearing or leaking. DESHENG's intelligent paper bag bottom pasting machine uses precise adhesive application technology to create strong and uniform seals.

Step details:

- Glue type and quantity are adjusted according to bag size and weight.

- Sensors monitor paste thickness to avoid over- or under-application.

- Reinforced bottom pasting options are available for extra durability.

This step directly affects bag strength and customer satisfaction, making precision equipment indispensable.

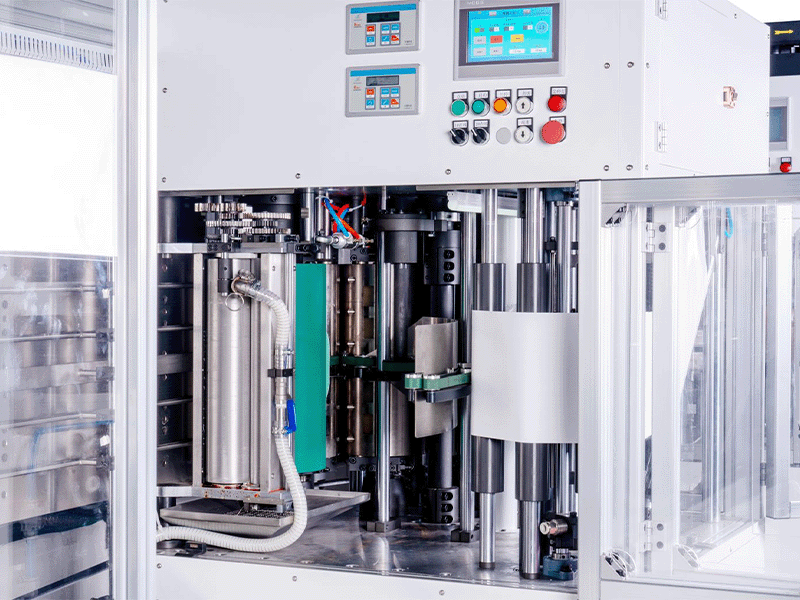

Step 4: Valve Insertion

The valve is what gives the valve bag its name and functionality. It allows for easy filling of powdery materials while keeping the bag airtight during transport. At DESHENG, our valve insertion units are fully automated and compatible with multiple valve sizes, ensuring smooth production.

Tips for efficiency:

- Align valves accurately to prevent misfeeds.

- Regularly check mechanical parts for wear and tear.

- Adjust speed settings based on material flow and bag size.

Step 5: Quality Inspection

High production speed must never compromise quality. Our DESHENG production line integrates automatic inspection systems that check bag dimensions, paste consistency, and valve alignment. Quality control at this stage reduces defects and customer complaints.

Key inspection checks:

- Bag length and width uniformity

- Valve attachment and sealing quality

- Bottom paste adhesion and strength

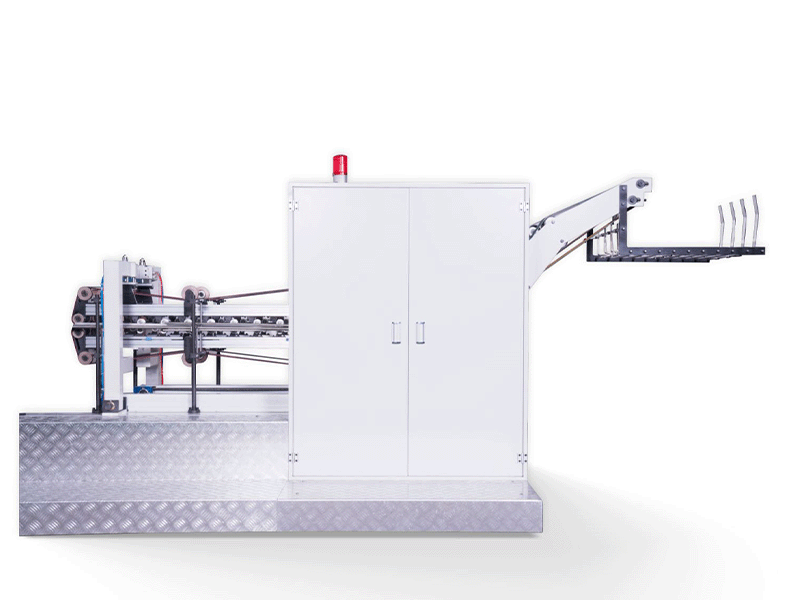

Step 6: Stacking and Packaging

After inspection, the bags are stacked and prepared for shipping. DESHENG offers automatic stacking units that organize bags neatly without damaging the bottom or valves. This stage can also include shrink-wrapping or palletizing for easier logistics.

Efficiency tips:

- Use conveyor systems to reduce manual handling.

- Integrate with robotic palletizers for fully automated lines.

- Consider labeling systems for batch tracking.

Step 7: Maintenance and Optimization

Running a valve bag production line efficiently requires regular maintenance. At DESHENG, we emphasize preventive maintenance and operator training to extend machine life and reduce downtime.

Recommended practices:

- Daily cleaning of adhesive units and cutting blades.

- Regular lubrication of moving parts.

- Monitoring electrical and pneumatic systems for optimal performance.

Why Choose DESHENG Valve Bag Machines

At DESHENG, we combine decades of experience with cutting-edge automation technology. Our valve bag machines and production lines are designed for:

- High-speed production with minimal downtime

- Reinforced bottom pasting for extra durability

- Fully automated valve insertion and stacking

- Integration with modern industrial automation systems

Factories worldwide trust our solutions to improve efficiency, reduce labor costs, and maintain consistent bag quality.

Conclusion

A valve bag production line involves multiple interconnected processes, each critical to producing durable, reliable bags. From material preparation and cutting to bottom pasting, valve insertion, and automated inspection, every step requires precision and expertise. At DESHENG, we design machines that streamline these processes, ensuring your production line runs smoothly and efficiently. Investing in high-quality machinery not only enhances productivity but also improves customer satisfaction and reduces operational costs.

Whether you're upgrading an existing line or starting a new project, DESHENG is your trusted partner in industrial valve bag production automation.

FAQs About Valve Bag Production Line

1. What is a valve bag and why is it used?

A valve bag is a type of industrial packaging bag equipped with a valve that allows for easy filling of powders and granular materials, such as cement, chemicals, or food powders. The valve ensures airtight sealing after filling, preventing contamination and spillage. At DESHENG, we manufacture reinforced valve bags that maintain their strength even during heavy-duty handling.

2. What materials are used to make valve bags?

Typically, valve bags are made from high-strength Kraft paper or multi-ply laminated paper. The choice of material depends on the weight and type of product to be packaged. Some applications require moisture-resistant or grease-proof papers, which our DESHENG machines handle effortlessly.

3. How does the bottom pasting machine work?

The paper bag bottom pasting machine applies adhesive to the bottom flaps of the bag to create a secure seal. DESHENG's intelligent bottom pasting machines are equipped with precise sensors to control glue application, ensuring uniformity and strength for all bag sizes.

4. Can DESHENG valve bag machines handle different bag sizes?

Yes, our valve bag machines are designed for versatility. Whether your factory produces small bags for chemicals or large cement bags, the machines can be adjusted to handle various dimensions without compromising efficiency or quality.

5. How much maintenance is required for a valve bag production line?

Regular maintenance is essential for smooth operation. At DESHENG, we recommend daily cleaning of adhesive and cutting units, regular lubrication of moving parts, and periodic inspection of electrical and pneumatic systems. Following these steps ensures minimal downtime and extends machine lifespan.

6. What are the main benefits of an automated valve bag production line?

Automated lines reduce labor costs, increase production speed, improve bag quality, and minimize material waste. DESHENG's fully automatic lines integrate cutting, folding, bottom pasting, valve insertion, inspection, and stacking, allowing factories to achieve consistent output with less manual intervention.

7. Can DESHENG machines integrate with existing production lines?

Absolutely. DESHENG's modular design allows for seamless integration into existing facilities. Our engineers assist with line configuration, ensuring compatibility with upstream and downstream equipment such as conveyors, palletizers, and quality inspection systems.

8. Are DESHENG valve bag machines suitable for cement, chemicals, and food powders?

Yes. DESHENG machines are designed for a wide range of applications, including heavy-duty cement bags, chemical powders, and granular food products. The machines' adjustable speed, valve insertion, and reinforced bottom pasting ensure reliable performance across all industries.