In industries where powders and granular materials dominate—such as cement, chemicals, food ingredients, fertilizers, and minerals—efficient and reliable packaging is critical. These materials are often dusty, free-flowing, abrasive, or sensitive to contamination, making them difficult to handle with conventional bagging solutions. This is where valve paper bag packaging machines stand out as an optimal choice.

Designed specifically for high-speed, clean, and accurate filling, valve paper bag packaging machines have become the preferred solution for manufacturers seeking productivity, consistency, and cost control. This article explores why valve paper bag packaging machines are ideal for powder and granular materials, how they work, and what makes them indispensable in modern industrial packaging lines.

Understanding Valve Paper Bag Packaging Machines

A valve paper bag packaging machine is a specialized bag filling system used to fill pre-made valve bags through a built-in valve or spout. Unlike open-mouth bags, valve bags seal automatically once filling is complete, thanks to internal air displacement and material pressure.

These machines are commonly referred to as:

- Valve bag filling machines

- Valve paper bag packers

- Powder packaging machines for valve bags

- Granular material valve bagging systems

They are widely used in fully automatic or semi-automatic packaging lines, especially where high throughput and dust-free operation are required.

The Unique Challenges of Powder and Granular Materials

Powder and granular products present specific packaging challenges that standard bagging equipment often struggles to overcome:

1. Dust Generation

Fine powders like cement, fly ash, flour, or chemical additives can easily become airborne, causing:

- Material loss

- Health and safety risks

- Equipment contamination

2. Flowability Variations

Some materials flow freely, while others are cohesive or prone to bridging, requiring precise filling control.

3. Weight Accuracy

Even small deviations in filling weight can lead to compliance issues, customer complaints, or increased costs.

4. Packaging Speed Requirements

High-volume industries demand fast, continuous packaging without compromising accuracy or bag integrity.

Valve paper bag packaging machines are specifically engineered to address these issues.

Key Reasons Valve Paper Bag Packaging Machines Excel with Powder and Granular Materials

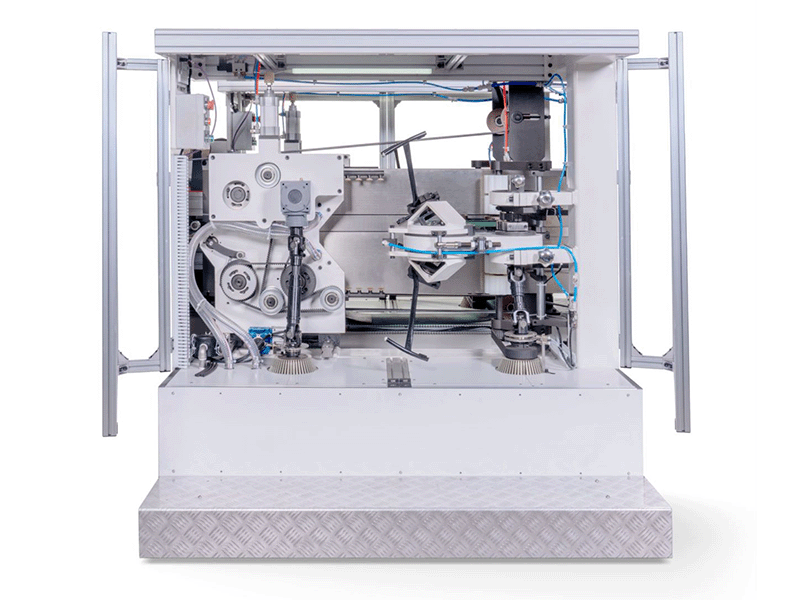

1. Dust-Free and Clean Filling Process

One of the biggest advantages of valve paper bag packaging machines is their excellent dust control.

- The filling nozzle inserts directly into the valve opening

- Material flows inside the bag without exposure to the surrounding air

- Air escapes through the porous paper bag rather than releasing dust

This makes valve bag packaging machines ideal for dusty powders, helping manufacturers maintain a clean production environment and comply with workplace safety standards.

2. High Filling Accuracy and Consistent Weights

Modern valve paper bag packaging machines use advanced filling technologies such as:

- Impeller filling

- Air-assisted filling

- Gravity filling with weight control

- Electronic weighing systems

These technologies ensure precise dosing, even for fine powders and mixed granular materials. Consistent bag weights reduce product giveaway and improve overall cost efficiency.

For industries where accuracy is non-negotiable—such as chemicals or food ingredients—this level of control is essential.

3. Automatic Bag Sealing Without Additional Equipment

Unlike open-mouth bags that require sewing or heat sealing, valve paper bags seal automatically after filling.

- Internal pressure closes the valve

- No extra sealing machinery is needed

- Packaging lines become simpler and more compact

This automatic sealing feature significantly improves line efficiency and reduces labor requirements, especially in high-speed operations.

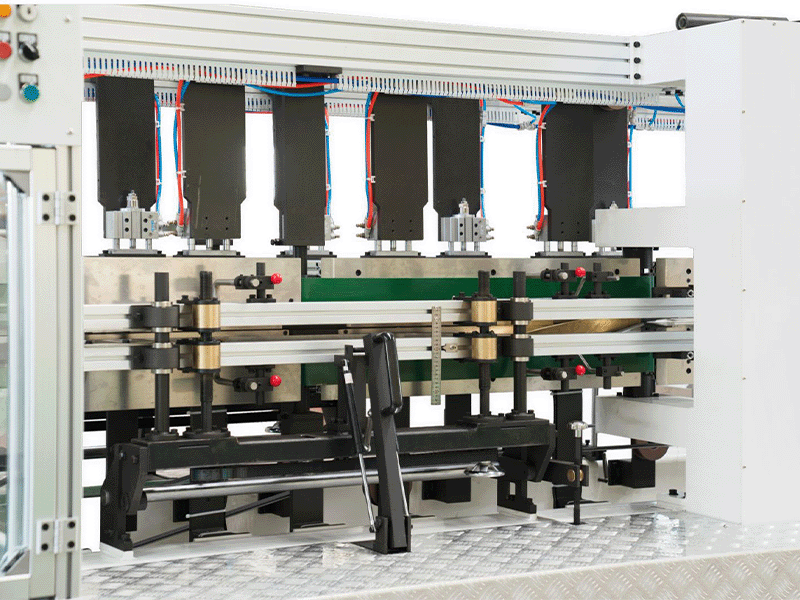

4. High-Speed Packaging for Large-Scale Production

Valve paper bag packaging machines are built for speed. Depending on the configuration, they can handle:

- Dozens to hundreds of bags per hour per spout

- Multi-spout systems for very high output

This makes them ideal for industries such as cement, building materials, fertilizers, and mineral processing, where large daily volumes are the norm.

Manufacturers looking to scale production often find that valve bag packaging machines provide the best balance between speed and reliability.

5. Excellent Compatibility with Powder and Granular Materials

Valve paper bag packaging machines can handle a wide range of materials, including:

- Cement and dry mortar

- Gypsum and lime

- Flour, starch, and food powders

- Chemical powders and additives

- Plastic resins and pellets

- Fertilizers and agricultural granules

By adjusting filling methods and airflow, these machines can be tailored to suit different material characteristics, from ultra-fine powders to coarse granules.

6. Reduced Material Loss and Lower Operating Costs

Material loss is a hidden cost in many packaging operations. With valve paper bag packaging machines:

- Dust leakage is minimized

- Spillage during filling is reduced

- Bag integrity is preserved

Over time, these advantages translate into lower operating costs, improved yield, and a faster return on investment.

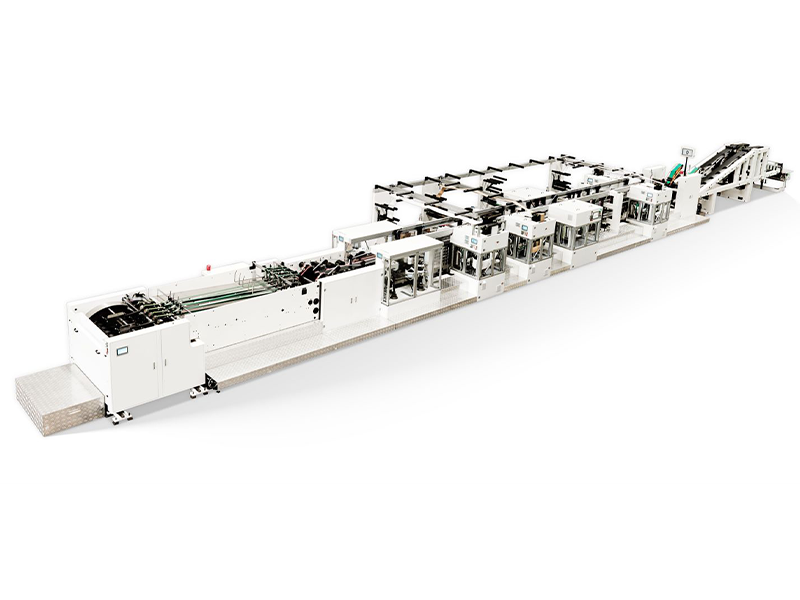

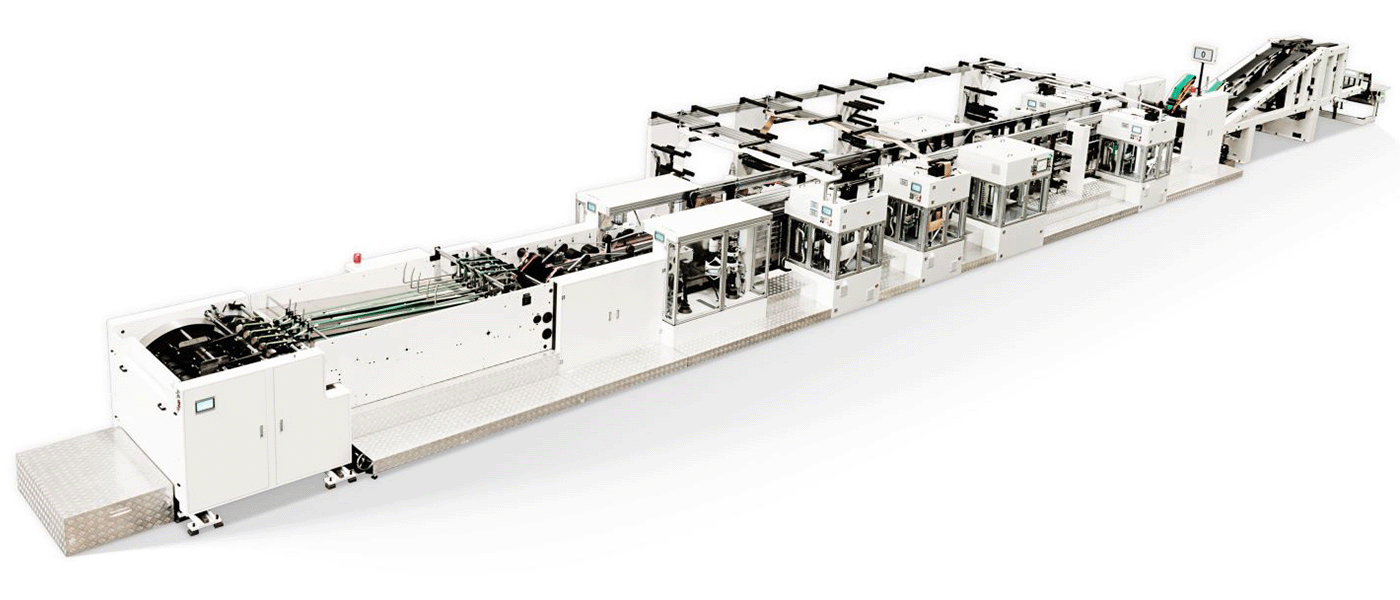

Automation Advantages in Modern Valve Paper Bag Packaging Lines

Today's valve paper bag packaging machines are increasingly integrated into automated production lines, including:

- Automatic bag placers

- Conveying systems

- Bag flatteners and palletizers

- PLC and HMI control systems

Automation reduces dependence on manual labor, improves consistency, and enhances traceability. Manufacturers aiming for smart factories and Industry 4.0 compliance often prioritize automated valve bag packaging solutions.

Why Paper Valve Bags Are Ideal for Powder Packaging

The choice of paper valve bags further enhances the effectiveness of these machines:

- Porous structure allows air release during filling

- Strong multi-layer construction supports heavy loads

- Eco-friendly and recyclable packaging option

- Excellent stackability for storage and transportation

When combined with a well-designed valve paper bag packaging machine, paper valve bags deliver both performance and sustainability.

Choosing the Right Valve Paper Bag Packaging Machine

When selecting a valve paper bag packaging machine for powder or granular materials, key considerations include:

- Material characteristics (density, flowability, abrasiveness)

- Required packaging speed

- Desired automation level

- Accuracy requirements

- Available plant space

Working with an experienced valve paper bag packaging machine manufacturer is critical to ensuring the system is properly configured for your application.

Manufacturers like DESHENG, for example, focus on developing valve paper bag packaging machines that balance precision, durability, and operational efficiency. With solutions designed for a wide range of powder and granular materials, DESHENG supports customers in achieving stable, long-term packaging performance rather than short-term gains.

Applications Across Multiple Industries

Valve paper bag packaging machines are widely used in:

- Cement and construction materials

- Chemical and industrial powders

- Food and ingredient processing

- Agriculture and fertilizer production

- Mining and mineral industries

Their versatility and reliability make them a long-term investment for manufacturers dealing with bulk powder and granular products.

Conclusion: The Ideal Solution for Powder and Granular Packaging

Valve paper bag packaging machines are purpose-built for the unique demands of powder and granular materials. Their dust-free operation, high filling accuracy, automatic sealing, and scalability make them superior to many alternative packaging methods.

For manufacturers seeking efficient, clean, and cost-effective packaging, valve paper bag packaging machines are not just an option—they are often the most practical and future-proof solution. With the right equipment partner, such as DESHENG, businesses can optimize their packaging lines and stay competitive in increasingly demanding markets.