Powder packing is one of the most challenging aspects of industrial production. Whether it is cement, flour, chemicals, or mineral powders, manufacturers face strict requirements for accuracy, efficiency, and safety. At DESHENG, we have spent years designing and supplying valve paper bag packaging machines that meet the high standards of powder packing operations worldwide.

In this article, we explore why valve paper bag packaging machines have become the preferred choice for powder packing, how they improve production efficiency, and how our solutions can help you achieve reliable and dust-free operations.

Understanding Powder Packing Challenges

Powder products, by their very nature, present unique challenges in packaging:

- Dust generation: Fine powders can easily escape during filling, creating environmental hazards and material loss.

- Weight accuracy: Overfilled bags lead to unnecessary cost, while underfilled bags can result in regulatory and customer complaints.

- High-speed requirements: Modern production lines often require filling hundreds to thousands of bags per hour.

- Sealing reliability: Powder leakage during transport can damage goods and affect customer satisfaction.

Traditional open-mouth bagging systems often struggle to meet these demands effectively. This is why valve paper bag packaging machines have become increasingly popular for powder packing applications.

What Is a Valve Paper Bag Packaging Machine?

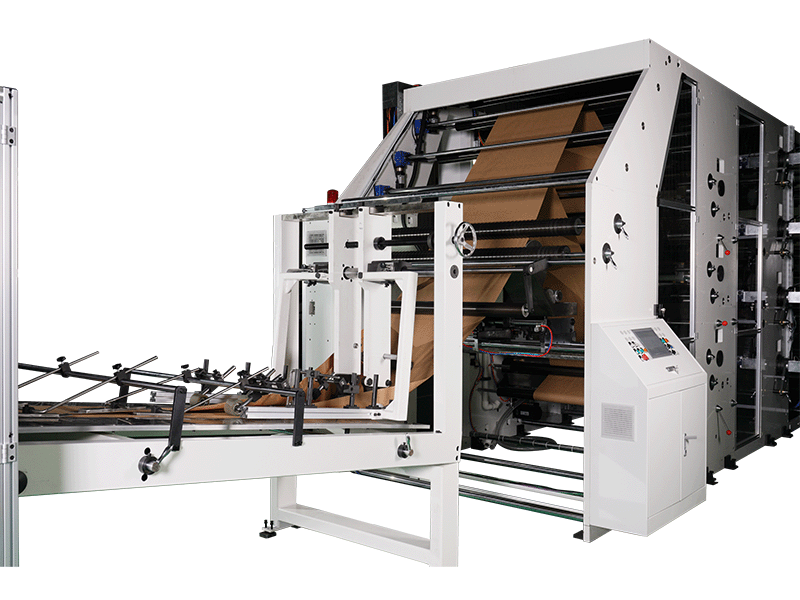

A valve paper bag packaging machine is a filling system designed to work with pre-made valve bags. These bags have a built-in valve that automatically closes once the bag is filled. Unlike open-mouth bags, the self-sealing feature reduces dust emissions and simplifies the bagging process.

At DESHENG, our valve paper bag packaging machines are designed specifically for powder products. They are suitable for a wide range of applications, including:

- Cement, gypsum, and lime powders

- Food powders such as flour, starch, and sugar

- Chemical powders and mineral products

We ensure that every machine is capable of handling both small and large-scale operations with precision and reliability.

Advantages of Valve Paper Bag Packaging Machines for Powder Packing

1. High Efficiency and Continuous Operation

Modern powder packing lines demand high-speed operation without compromising quality. A valve paper bag packaging machine can fill bags continuously at high speed.

At DESHENG, we engineer our machines to maintain stable performance over long shifts, allowing you to achieve high production output while reducing labor requirements. Our automatic models can integrate seamlessly into fully automated powder packing lines for maximum efficiency.

2. Precise Bag Weight and Dosing Accuracy

Accurate bag weight is critical in powder packing. Our valve paper bag packaging machines are equipped with mechanical or electronic dosing systems that ensure every bag is filled according to specification.

- Reduce material waste from overfilling

- Avoid regulatory issues due to underfilling

- Improve overall production consistency

We work closely with our clients to customize weighing systems depending on product type and production volume, making sure that accuracy meets your operational standards.

3. Dust-Free and Cleaner Production

Dust control is one of the main reasons manufacturers choose valve paper bag packaging machines. Unlike open-mouth baggers, valve systems prevent powder from escaping during the filling process.

- The bag's valve closes automatically after filling

- The enclosed spout design minimizes airborne dust

- Optional dust extraction interfaces are available for extra protection

At DESHENG, we optimize spout designs to handle even the finest powders, ensuring a clean, safe, and efficient working environment.

4. Reliable Sealing and Bag Integrity

Valve bags automatically seal after filling, providing a secure and reliable solution for powder packing. This sealing method:

- Reduces the risk of leakage during transport

- Maintains bag shape and stackability

- Preserves product quality and appearance

Our machines ensure consistent sealing performance, which is particularly important for powders with high commercial value or those intended for export.

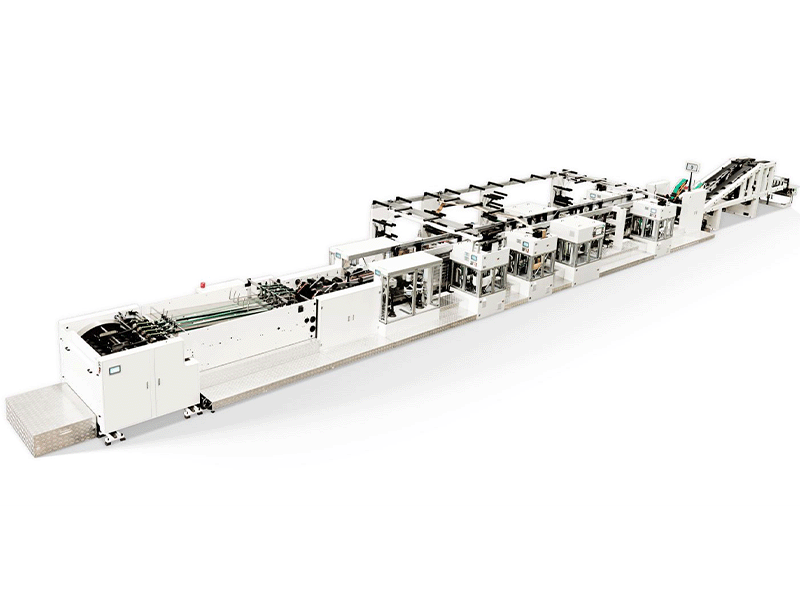

5. Flexible Integration with Powder Packing Lines

A valve paper bag packaging machine can be a standalone solution or part of a fully automated packing line. At DESHENG, we provide equipment that can integrate with:

- Bag conveyors and elevators

- Bag flatteners and checkweighers

- Palletizers, robotic or conventional

This flexibility allows manufacturers to scale operations and automate processes according to production needs, reducing labor dependency and improving overall efficiency.

6. Adaptability for Different Powder Products

Not all powders behave the same. Factors such as particle size, flowability, and abrasiveness affect filling performance. DESHENG valve paper bag packaging machines are versatile, capable of handling a variety of powders without compromising speed or accuracy.

Whether you pack cement, flour, starch, or mineral powders, our machines can be tailored to meet the unique demands of your product.

Choosing the Right Valve Paper Bag Packaging Machine

When selecting a valve paper bag packaging machine, several factors must be considered:

- Production capacity – Bags per hour and weight range

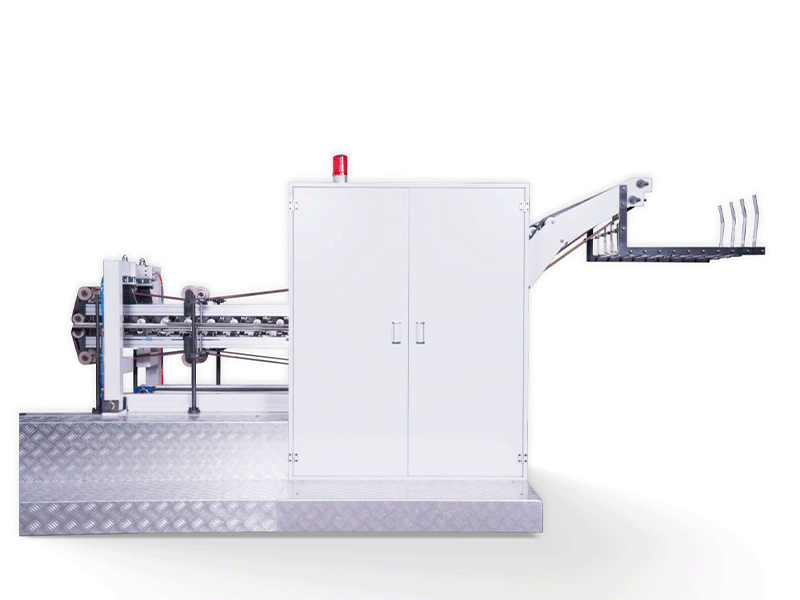

- Automation level – Semi-automatic vs fully automatic systems

- Powder characteristics – Flowability, abrasiveness, and dustiness

- Integration needs – Ability to connect with conveyors, checkweighers, and palletizers

We at DESHENG provide detailed consultation to help manufacturers choose the most suitable solution. Our focus is on building machines that are reliable, easy to maintain, and capable of long-term operation.

Maintenance and Longevity

Powder packing machines operate in harsh environments, where wear and tear is inevitable. DESHENG designs machines using high-quality materials and durable components, ensuring:

- Long operational life

- Minimal downtime

- Simple maintenance procedures

Regular preventive maintenance further enhances machine performance, ensuring your powder packing line runs smoothly year after year.

Conclusion

Valve paper bag packaging machines have proven themselves as the preferred choice for powder packing due to their accuracy, efficiency, dust control, and reliability. At DESHENG, we focus on creating machines that meet the real challenges faced by powder manufacturers, from cement and chemicals to food products.

By investing in a valve paper bag packaging machine, you can improve production efficiency, maintain consistent bag quality, and ensure a cleaner, safer working environment. With DESHENG, you are choosing a trusted partner for long-term powder packing solutions.